Bert Jones Yacht Basin Bulkhead, Dredging & Replacement

Gulf Coast Pre-Stress

Location:

City of Gulfport

Gulfport, MS 39501

Schedule:

Project Start Date: 05/18/2009

Project Completion Date: 05/05/2011

Cost:

Total Project Cost: $19.5 million

Square Footage: 116,163 SQ

Cost of Precast Concrete: $6.6 million

Involved Companies

Precast Concrete Producer

Gulf Coast Pre-Stress

494 N. Market Street

Pass Christian, MS 39571

http://www.gcprestress.com/

Engineer of Record

Brown, Mitchell & Alexander, Inc

521 34th Street

Gulfport, MS 39507

http://www.bmaengineers.com/

Architect

Eley Guild Hardy

1041 Tommy Munro Drive

Biloxi, MS 39532

https://eleyguildhardy.com/

Structural Engineer

Simpkins & Costelli, Inc

401 33rd Street

Gulfport, MS 39507

http://simpkins-costelli.com/

Precast Concrete Specialty Engineer

Gulf Coast Pre-Stress

494 N. Market Street

Pass Christian, MS 39571

http://www.gcprestress.com/

General Contractor

Innovative Builders, Inc.

10750 Highway 603

Bay St. Louis, MS 39520

http://www.innovativebuilders.com/

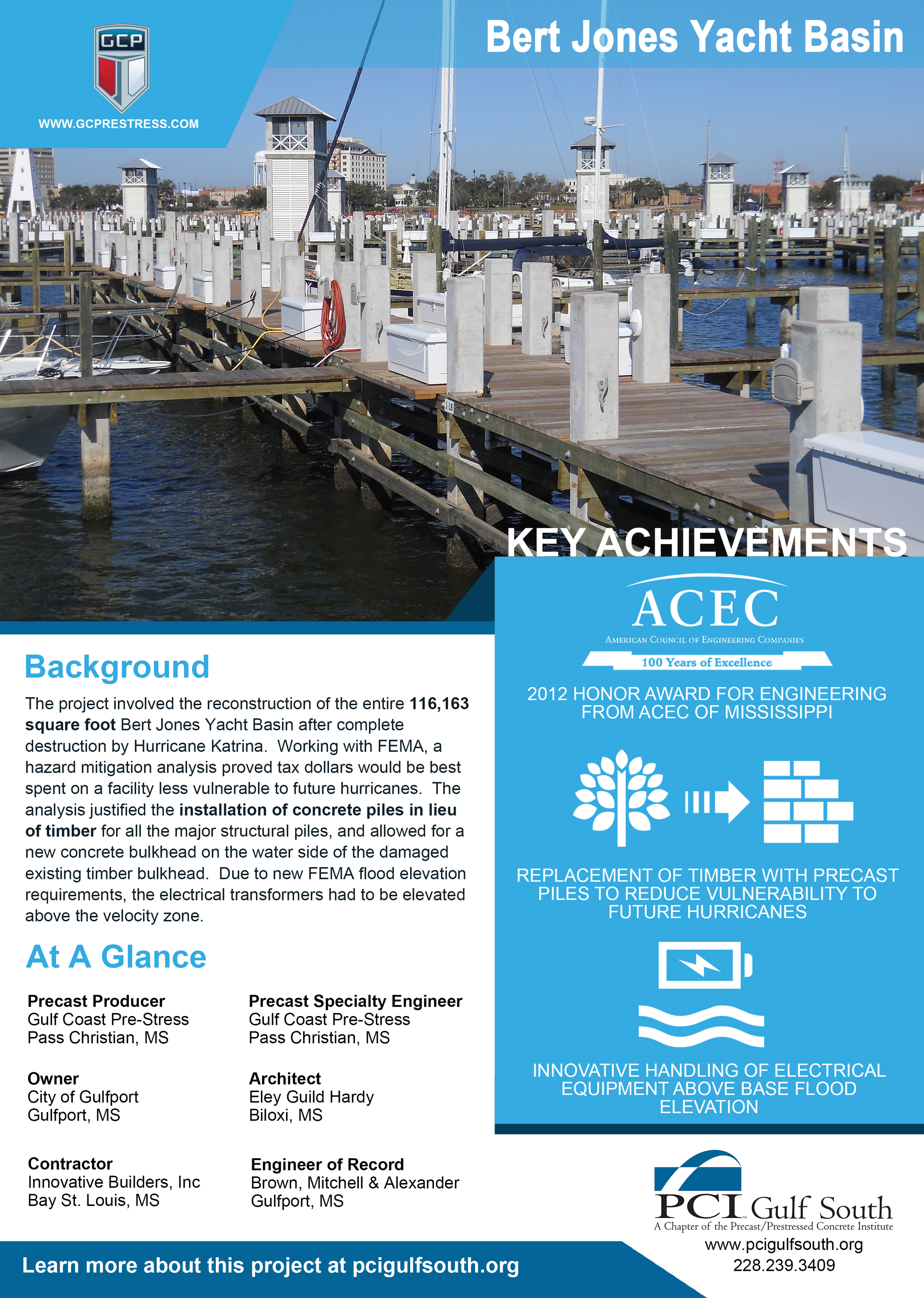

Background

This project involved the reconstruction of the entire Bert Jones Yacht Basin after complete destruction by Hurricane Katrina. Working with FEMA, a hazard mitigation analysis proved that tax dollars would be better spent to design a facility less vulnerable to future hurricanes. The analysis justified the installation of concrete piles in lieu of timber for all the major structural piles, and allowed for a new concrete bulkhead on the water side of the damaged existing timber bulkhead. Due to new FEMA flood elevation requirements, the electrical transformers had to be elevated above the velocity zone, therefore elevated towers housing these transformers provide not only an aesthetically pleasing structure but also allows for additional storage areas and shade. This "storm-hardened" philosophy resulted in construction of a perimeter bulkhead utilizing pre-stressed concrete piles, pre-cast concrete sheet piles and poured concrete pile caps and walks; reconstruction of piers including concrete piles, timber framing and decking; and elevated transformer towers constructed with a nautical themed facade, one of which resembles a lighthouse structure. The overall reconstruction and improvements resulted in a low maintenance, user friendly 319 boat slip harbor equipped with electricity, potable water, fire suppression and vacuum wastewater systems.

Precast Components:

2,408 LF of concrete bulkhead

24,190 LF of 16” x 16” concrete piles

83,975 LF of 16” x 14” concrete piles

Challenges

The project contained the complexity of reconstruction of a harbor within the boundaries of the existing damaged harbor, complexities with funding, coordination with state and federal agencies and construction in and on the water. Elevating electrical towers and installing new concrete perimeter bulkhead (described in more detail below) were design challenges. The combination of concrete structural components allowed for expediting the construction of many aspects of this project.

Innovations/Accomplishments

The project was designed to include an innovative handling of electrical equipment which had to be positioned above Base Flood Elevation (BFE). Because of the height requirement and restrictions on spacing, the elevated platforms, built with pre-stressed concrete piles, were installed over the water providing for architecturally pleasing structures which also provide some maintenance equipment storage and shade. In addition, a new concrete perimeter bulkhead consisting of pre-stressed concrete piles, pre-cast concrete sheet piles and poured concrete pile caps and walks was constructed within 10' of the existing damaged timber bulkhead (originally constructed in 1934).

This project received a 2012 Honor Award for Engineering Excellence presented by the American Council of Engineering Companies of Mississippi.