Precast and the Design Assist Process

The term "design assist" currently refers to a recent tendency toward early integration of the design/build process. This method was initially applied when the design team, contractors, and owner worked together early in the design phase to include environmental goals in project planning. It was immediately determined that the advantage of this method is its capacity to adapt to clients' increasing needs for projects to be delivered more rapidly, sustainably, and uniformly, with less danger of price increase. To meet these requirements, the building crew must work closely and quickly together.

How the Process Works

When a design team engages a precaster for "design assist," they typically intend to procure precast concrete early in the design process to take advantage of the precaster's knowledge and recommendations to choose the most effective techniques, sizes, finishes, etc. and maximize efficiency across the project.

Design assist is the contemporary trend toward adopting the design/build delivery technique. This is shown to improve processes often by utilizing the collective experience of all participants. It can inspire better solutions for achieving expedited timelines, lowering risk, and preventing price increases.

Preliminary Design

To start the design assist process, the project team creates a preliminary plan, including drawings of the building's sections, elevations, typical wall sections, floor plans, special loading information, occupied areas, and outline requirements. The precast can then use those materials to create a comprehensive estimate with a guaranteed scope and timeline.

Design Phase

After multiple design sessions, these ideas are examined and modified to determine the most effective design that satisfies the owner's requirements while producing precast concrete components. The precaster’s project management team members, such as their project manager or engineer, often attend the meetings. When required, a precast can also offer estimation services, suggestions, and counsel for precast design, fabrication of the components, erection methods and schedules, and transporting.

Finalization

The contract amount and timeline are modified to reflect any deviations from the initial scope of work after design development is complete. To guarantee that the project budget and construction schedule are preserved, these modifications occur early in the process.

The precaster in this process becomes a more active participant in counseling the architect and engineer of record rather than taking their place. The building's structural layout and conceptual design remain under the purview of the architect and engineer. The precaster uses their unique experience and efficiency to affordably achieve these objectives. This might entail value-engineering some structure elements or just creating the proper timetable.

Consider taking PCI's free eLearning course, Efficient Design Assist, to learn more about how the design assist process works with precast. This online course will discuss the importance of adding precasters to the team earlier in the construction process, discuss the best way to use precasters to assist the project delivery team, and cover how evolving design roles are shaping the future of the concrete industry.

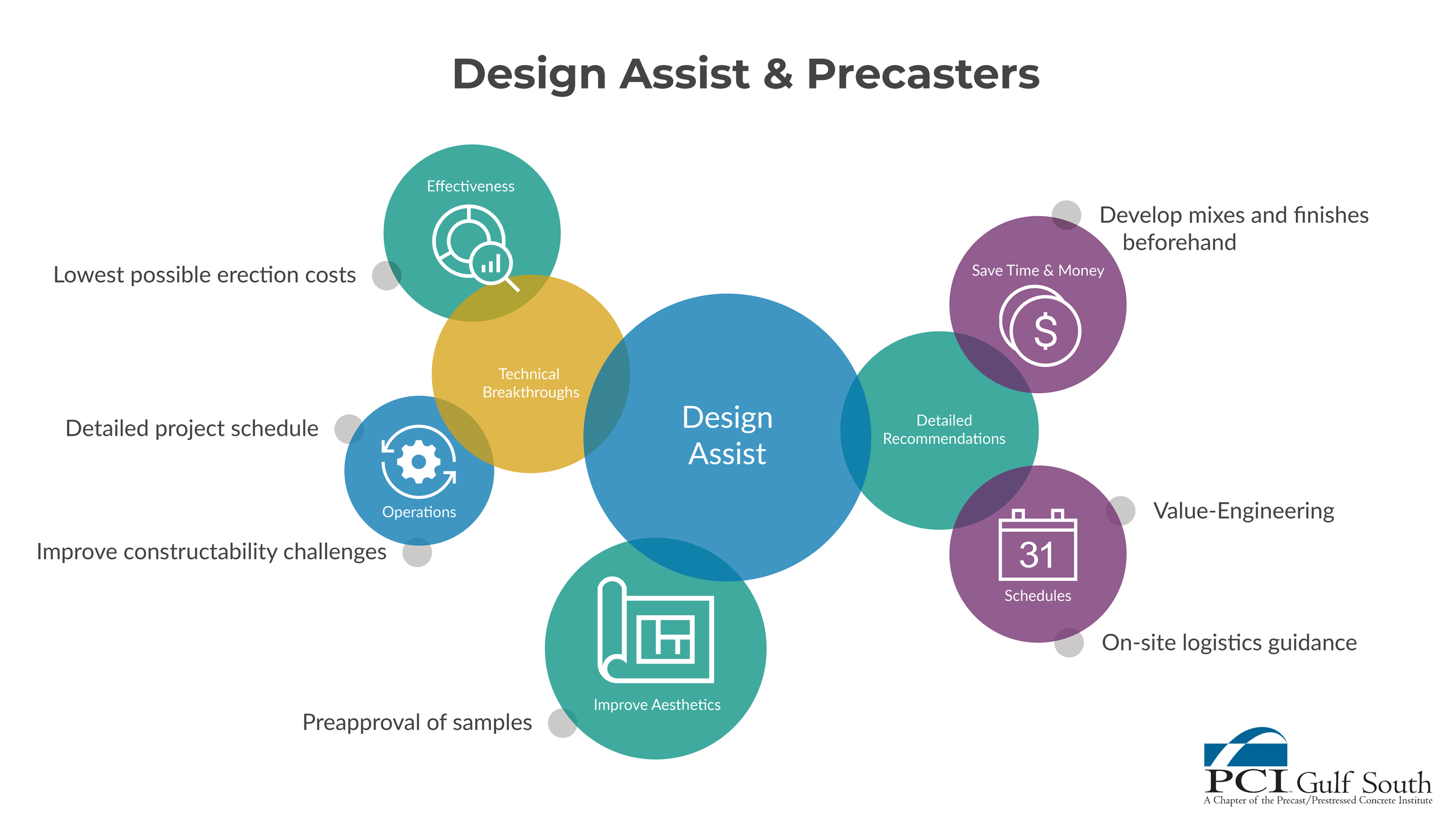

Benefits of Design Assist Process

Precasters provide in-depth knowledge that enables technical breakthroughs and scheduling improvements that speed up design development, improve aesthetics, and keep costs under control from the initial concept to project completion. Each part may be constructed as inexpensively as feasible using the precast concrete's built-in performance qualities. The precaster will be able to offer design and detailed recommendations to guarantee that the highest level of effectiveness is attained at the lowest possible cost of erection. The end product should be an operationally effective and aesthetically beautiful enclosure that meets or exceeds the project's requirements.

A predetermined schedule and a defined cost for the precast work are two of the method's main advantages. Based on the general information provided by the owner's design team, precasters will use their experience and expertise to create a guaranteed design assist proposal that can include a detailed scope description, preliminary drawings, a Gantt chart schedule, erection logistics, or other specific project information.

The following are additional advantages of the design-assist method:

Saving time and money by developing concrete mixes and finishes beforehand rather than waiting until after the bid and award process to approve samples

The budget is continually monitored so that new pricing information can be supplied

Value-engineering ideas that use precast concrete's benefits are suggested as soon as possible to cut costs

Providing guidance on-site logistics and constructability challenges

Taking part in the creation of a detailed project schedule

Shortened lead times thanks to an early agreement among all parties

Architectural precasters can review PCI’s free Designer Notebook on Architectural Precasters’ Design Assist Role and how it can benefit all sized projects here.

Key Takeaways

The process of design assist can help save a lot of time, money, and revisions. It helps to guarantee that the owner receives the project without unexpected delays or overruns, on schedule, and within budget.