Lee County AL Overpass @ Moore’s Mill Road on I-85 in Auburn Alabama

Forterra

Location:

Alabama DOT

Montgomery, AL

Schedule:

Project Start Date: 2/26/2016

Project Completion Date: 06/01/2018

Cost:

Total Project Cost: $10M

Involved Companies

Precast Concrete Producer

Forterra

400 Industrial Park Drive

Pelham, AL 35124

https://forterrabp.com/

Engineer of Record

Alabama Department of Transportation

1409 Coliseum Blvd.

Montgomery, AL 36110

https://www.dot.state.al.us/

General Contractor

Scott Bridge Company, Inc.

2641 Interstate Drive

Opelika, AL 36804

http://www.scottbridge.com/

Background

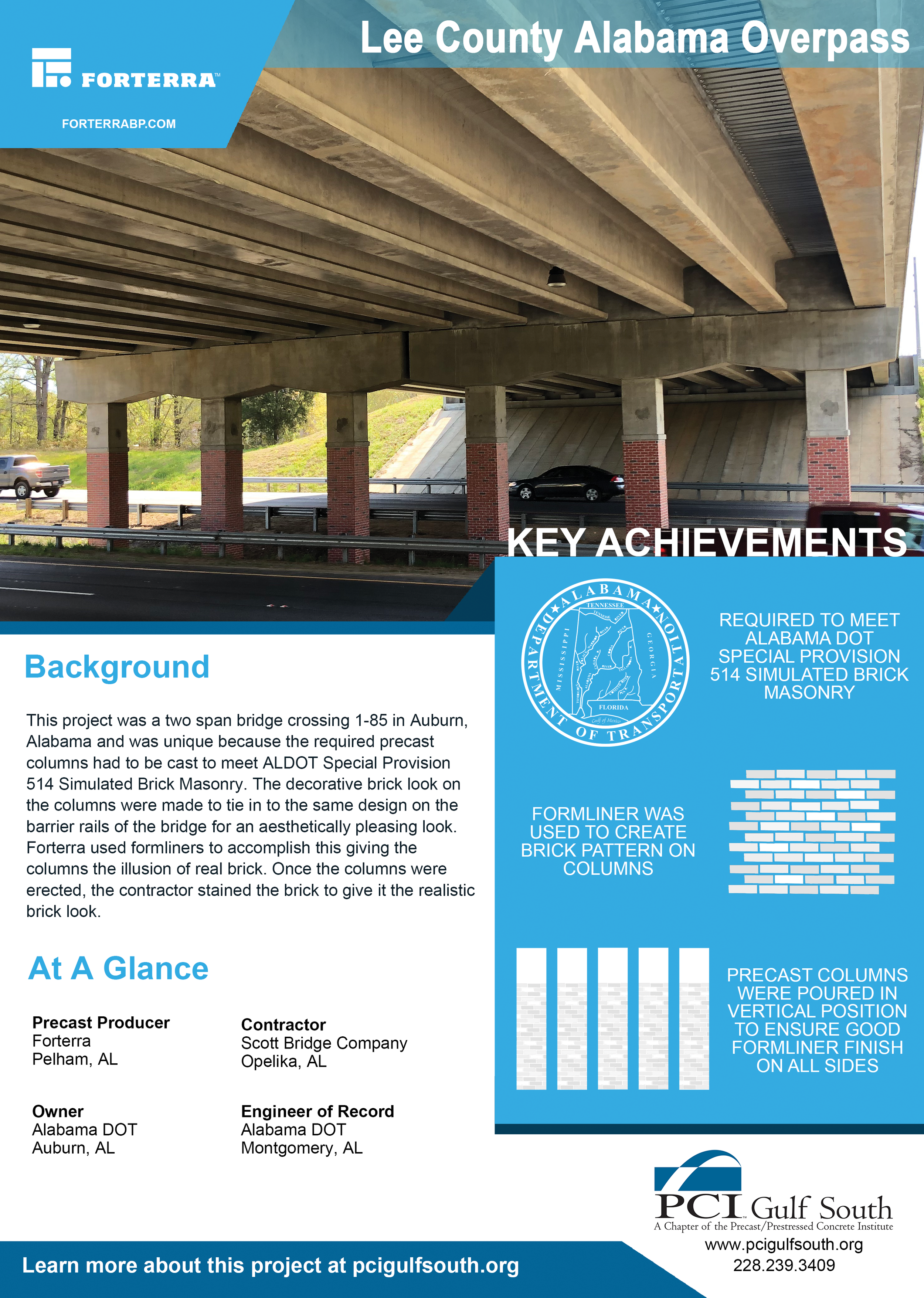

This project was a two span bridge crossing 1-85 in Auburn, Alabama and was unique because the required precast columns had to be cast to meet ALDOT Special Provision 514 Simulated Brick Masonry. The decorative brick look on the columns were made to tie in to the same design on the barrier rails of the bridge for an aesthetically pleasing look. Forterra used formliners to accomplish this giving the columns the illusion of real brick. Once the columns were erected, the contractor stained the brick to give it the realistic brick look.

Structural Products included:

2,836 LF of 54" Bulb Tee Modified Girders (24 Girders @ 118—2" Long) 6 Ea.

3'-0" X 3'-0: x 19-9" Precast Concrete Columns utilizing Brick liners in forms

Challenges

The contractor revised the original precast column to foundation connection in order to improve constructability. The resulting connection utilized splice sleeves in the base of the precast columns with dowels projecting from the CIP footing. This change also helped with production issues discussed below.

The main challenge for the precaster was how to get a nice brick formliner finish on all four sides of the column. Typically, precast columns have been cast in the horizontal position. The solution to this problem required Forterra to pour the columns standing vertical. By changing the base connection and using a concrete pumping operation, Forterra was able to accomplish this. By pouring columns in the upright position, Forterra was able to get the liner finish uniformly applied to all four sides of the product.