New Orleans BioInnovation Center

Jackson Precast

Location:

New Orleans BioInnovation Center

New Orleans, LA

Schedule:

Project Start Date: 10/2009

Project Completion Date: 2011

Cost:

Total Project Cost: $38 million

Square Footage: 63, 980 SF

Involved Companies

Precast Concrete Producer

Jackson Precast

3325 Lawson St

Jackson, MS

https://www.jpi.ms/

General Contractor

Turner Universal

624 Grassmere Park Drive

Nashville, TN

http://www.turnerconstruction.com/

Architect

Eskew+Dumez+Ripple

365 Canal Street

New Orleans, LA

www.eskewdumezripple.com

Background

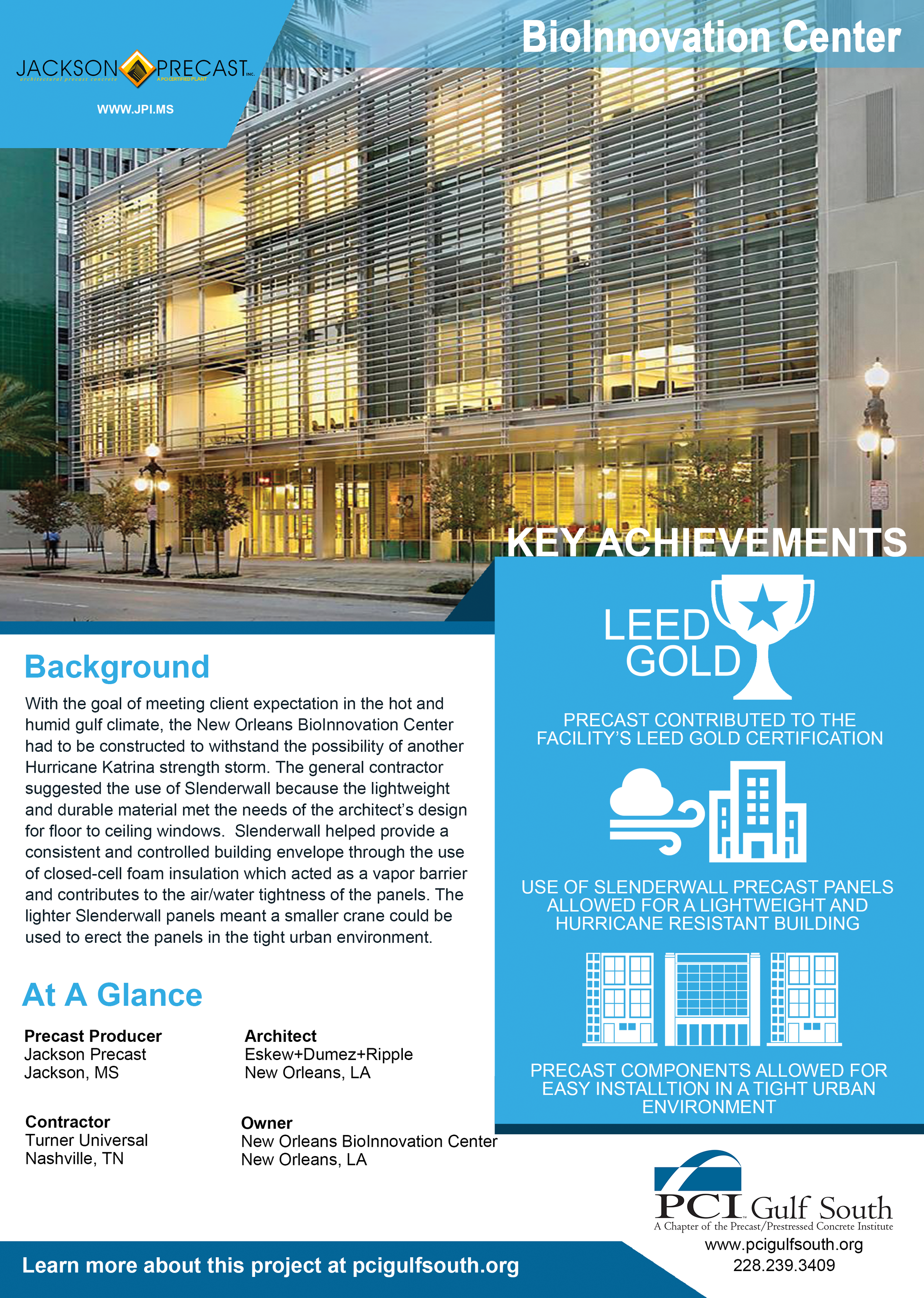

The BioInnovation Center is a hub of start-up, non-profit lab and office facilities in the biotech industry. The goal of the facility was to serve local businesses with the overall result of creating local jobs and industries. The facility is a four-story, 64,000 SF building surrounded by the New Orleans French Quarter, university campuses, and the Treme neighborhood. The center is built on a brownfield site and was designed to help revitalize the neighborhood and generate over 200 jobs. The facility houses labs, conference rooms, breakout spaces, and a cafe.

Challenges

With the goal of meeting client expectation in the hot and humid gulf climate, the New Orleans BioInnovation Center had to be constructed to withstand the possibility of another Hurricane Katrina strength storm.. Because the building houses intense energy using laboratory equipment, the issue of energy efficiency was a particular challenge.

Innovations/accomplishments

The BioInnovation Center was the first laboratory building in Louisiana to achieve LEED Gold certification as a result of various sustainable features. The sustainable design features include:

An outdoor water feature that also serves as a basin to capture rainwater and AC condensation which provides water to all the building’s landscaping

Careful design which allows for more windows while reducing the solar gain of the facade

75% of the building facade provides daylight to illuminate the facility resulting in less energy usage during the day

Building facade includes glaze that provides solar controls to assist with building temperature

However, the most impressive of all the innovations on this project was the use of precast, more specifically Slenderwall by Jackson Precast. The general contractor suggested using Slenderwall which met the needs of the architects to have a lightweight and durable material that could accommodate floor to ceiling windows. Slenderwall provides a consistent and controlled building envelope through the use of closed-cell foam insulation which acts as a vapor barrier and contributes to the air/water tightness of the panels.

Precast was also a good choice because it was produced in Jackson’s offsite precast plant and delivered to the tight urban site ready to install. The limited crane access on the tight project space also made Slenderwall a perfect choice in building material. If traditional precast components had been used, a larger crane would have been needed. Slenderwall also met the local hurricane codes in terms of wind and impact resistance.

Awards

Top Ten Project Award, 2015, AIA’s Committee on the Environment

New Orleans Honor Award, 2012, AIA

Louisiana Honor Award, 2012, AIA

Winner, 2016, U.S. Small Business Administration Growth Accelerator Fund Competition

Good Design is Good Business Award Winner, 2014, Architectural Record

Green Architecture Good Design Award, 2014, The European Centre for Architecture Art Design and Urban Studies and The Chicago Athenaeum: Museum of Architecture and Design

Award of Excellence: Sustainable Commercial Design, 2014, International Interior Design Association, Delta Region

American Architecture Award, 2013, The Chicago Athenaeum: Museum of Architecture and Design

Information from AIA and SlenderWall | Photos via BioInnovation Center Facebook Page