Design Trends with Precast Concrete in Educational Facilities

Picture this: a classroom buzzing with energy, where walls don't just hold up the roof but inspire minds, and floors aren't just surfaces but pathways to discovery. Prepare to be transported into a world where imagination meets innovation, where precast concrete isn't just a material but a storyteller in the narrative of education.

Picture this: a classroom buzzing with energy, where walls don't just hold up the roof but inspire minds, and floors aren't just surfaces but pathways to discovery. Prepare to be transported into a world where imagination meets innovation, where precast concrete isn't just a material but a storyteller in the narrative of education.

Benefits of Using Precast Concrete in Educational Facilities

When used in educational institutions, precast concrete has several advantages.

Because of its natural resilience, it lasts longer in high-traffic areas and gradually requires less maintenance.

Design flexibility makes customized learning environments possible, which boosts student creativity and engagement.

The sustainability qualities of precast concrete provide environmentally friendly construction methods that complement the environmental objectives of educational institutions.

Precast concrete is a recommended material for contemporary educational facility design because of these advantages. When combined, they provide engaging and practical learning environments that prioritize students' health, safety, and academic performance.

Design Trends with Precast Concrete

Innovative design concepts have revolutionized educational facilities by transforming conventional classrooms into dynamic learning spaces. Modern design techniques paired with precast concrete transform learning environments to improve student participation, health, and academic performance.

Natural Light and Open Spaces

Designing educational spaces with lots of natural light and open floor plans promotes a good learning environment. Students benefit from natural light as it increases their alertness and focus, and they may collaborate, be creative, and feel free in open areas. Precast can support longer spans, which means fewer columns and walls to break up open spaces.

Technology-Friendly Features

Modern classroom technology, such as interactive whiteboards, smart boards, and digital resources, improves student involvement and the efficacy of instruction. These characteristics support the development of digital literacy and interactive learning experiences. Precast can be integrated with all types of systems, from plumbing to electrical, to provide the best of both worlds in terms of construction and technology.

Biophilic Design Elements

Using biophilic design elements, such as indoor plants, green walls, and natural materials, fosters wellbeing and a connection between students and the natural world. Improved air quality, less stress, and a peaceful, motivating environment for learning are all benefits of biophilic design. Precast is mold-resistant and is a perfect home for plants and other natural materials.

Modular and Flexible Furniture Arrangements

Flexible seating arrangements and modular furniture enable classrooms to change to accommodate various teaching philosophies and student preferences. This adaptability promotes teamwork, active learning, and the personalization of learning environments to suit various educational requirements. Precast can be used to create spaces that allow for the free movement of desks and other school furniture, supporting this adaptability.

Sustainable Design Practices

Incorporating eco-friendly elements like green roofs, energy-efficient lighting, and rainwater harvesting systems increases environmental consciousness and lessens the ecological impact of educational structures. Sustainable design principles encourage students to adopt sustainable behaviors and are consistent with educational institutions' environmental stewardship values. Precast not only reduces future maintenance for schools but also provides resistance to storms, increasing structures' lifespans.

Best Practices for Implementing Precast Concrete in Educational Buildings

Adherence to best practices and cooperative efforts are necessary to successfully use precast concrete in educational facilities. To ensure that design purpose matches educational objectives, key issues include efficient communication and collaboration among architects, designers, educators, and construction teams. Maintaining long-term functionality and beauty requires careful consideration of accessibility, safety regulations, acoustic performance, and routine maintenance and upkeep techniques. Educational buildings can use the advantages of precast concrete and create inspirational and useful environments that promote student learning, creativity, and wellbeing by prioritizing these best practices.

Future Directions and Innovations

Exciting developments and inventions in precast concrete for educational buildings are anticipated in the future. Some of the developments that are anticipated include more integration of smart technologies to improve learning, the creation of environmentally friendly building materials and techniques, and the use of flexible and adaptive designs to meet changing needs in education. These developments align with the continuous development of learning environments, guaranteeing that precast concrete will be essential to constructing dynamic, motivating, and long-lasting learning spaces for future generations.

Final Thoughts

The design trends, best practices, and future innovations discussed showcase the transformative potential of precast concrete in creating inspiring and functional educational buildings. To delve deeper into how precast concrete is the right choice for schools, we invite you to view our school-focused resources. Explore the benefits, success stories, and expert insights demonstrating why precast concrete is the ideal solution for modern educational environments!

Cost-Efficiency and Longevity: Evaluating the Life Cycle of Precast Concrete

Precast concrete is unique among building materials because of its affordability, toughness, and adaptability. By analyzing its extensive life cycle assessment, affordability, resilience, and environmental sustainability, we reveal its significant influence on contemporary building methods and infrastructure advancement.

Precast concrete is unique among building materials because of its affordability, toughness, and adaptability. By analyzing its extensive life cycle assessment, affordability, resilience, and environmental sustainability, we reveal its significant influence on contemporary building methods and infrastructure advancement.

Understanding Precast Concrete

Precast concrete is a versatile and durable construction material that is made off-site in controlled environments and then delivered to construction sites. It includes a wide variety of structural components made with molds and curing procedures, such as walls, columns, beams, slabs, and panels.

Precast concrete has several benefits, such as quick installation that minimizes labor on-site, high-quality manufacture under strict quality control procedures, and the capacity to modify designs to meet project-specific specifications. Its applications cover infrastructure, commercial, industrial, and residential buildings, making it a top pick for long-lasting and reasonably priced building solutions.

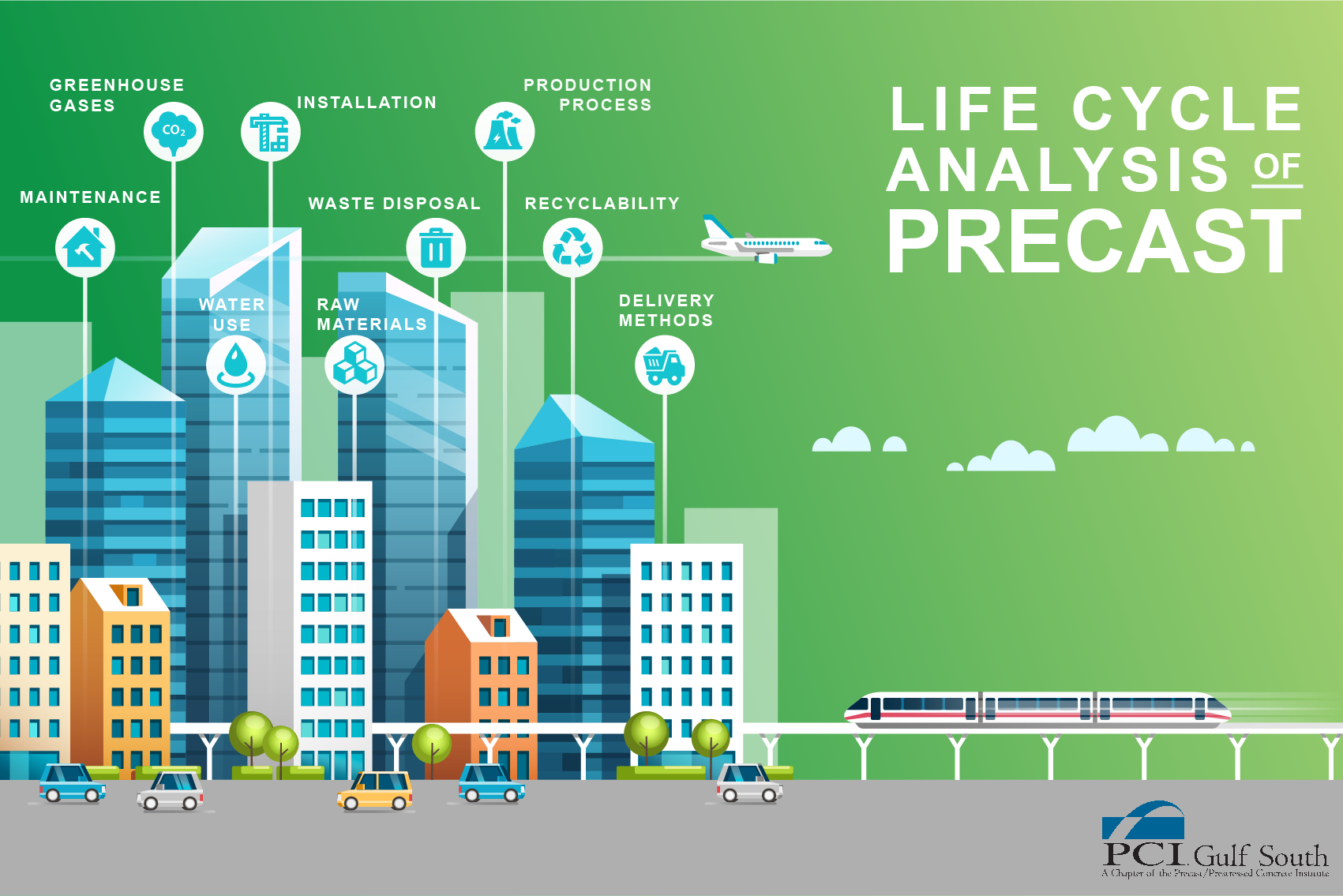

Precast’s Life Cycle Assessment (LCA)

A systematic analysis technique called life cycle assessment (LCA) is used to assess how a product or process will affect the environment at each stage of its life cycle, from the extraction of raw materials to disposal. LCA is essential for evaluating sustainability indicators in the context of precast concrete, including:

greenhouse gas emissions

water use

environmental impact of extracting raw materials

energy-intensive production processes

transporting completed goods

installation techniques

maintenance needs

end-of-life issues like disposal or recyclability

By conducting a thorough life cycle assessment (LCA), stakeholders can maximize precast concrete's environmental performance, pinpoint opportunities for development, and advance sustainable practices in the building sector.

Cost-Efficiency of Precast Concrete

Precast concrete is becoming widely used in construction projects due in large part to its cost-effectiveness. Precast concrete offers considerable labor, time, and cost reductions over typical cast-in-place concrete processes. Construction schedules are shortened, and the amount of manpower needed on site is reduced because of the off-site manufacturing method, which enables simultaneous production and on-site preparation.

Precast concrete is more affordable when production conditions are regulated, manufacturing procedures are standardized, material waste is decreased, and quality control is enhanced. Additionally, because precast concrete is naturally durable and resistant to environmental deterioration, using it can result in lower maintenance expenditures over the course of a structure's lifetime.

Project stakeholders can attain expedited construction timelines, decreased project costs, and improved long-term value through the reduction of maintenance and operations expenses by utilizing the cost-effectiveness of precast concrete. Because of this, precast concrete is an excellent option for building projects in a variety of industries that are driven by efficiency and cost concerns.

Longevity and Durability

Precast concrete's lifespan and durability are important factors to consider when evaluating its life cycle. Precast concrete buildings are famous for their extraordinary strength, resistance to weathering, and long-term durability in a variety of environmental circumstances. For infrastructure development, precast concrete is an affordable and environmentally friendly option because it requires less future maintenance and has a longer lifespan than traditional construction techniques.

Precast concrete's durability is further increased by its resistance to fire, corrosion, and seismic stresses, which guarantees structural integrity and safety throughout time. These characteristics make precast concrete the perfect choice for important infrastructure projects, including roads, bridges, buildings, and other structures that need to last a long time.

Environmental Sustainability

Precast concrete is acknowledged for making major contributions through its life cycle to environmentally sustainable building practices. Compared to conventional concrete processes, its production process minimizes waste formation, consumes less energy, and efficiently uses the ingredients. Precast concrete buildings also have a smaller carbon footprint and, because of their improved thermal qualities, improve building energy efficiency.

Precast concrete's capacity to be recycled helps to further advance sustainability by lowering trash sent to landfills and preserving natural resources. Precast concrete is the material of choice for environmentally aware construction projects that aim to reduce their negative effects on the environment and encourage sustainable growth because of these advantages over other materials that are in line with green building standards and certifications.

Future Trends and Innovations

Precast is expected to continue to progress and innovate in order to improve performance, efficiency, and sustainability. The development of sustainable materials and practices to lessen environmental impact, automation of production processes for increased efficiency and quality control, and the integration of digital software like BIM for precise modeling and coordination are some of the key trends.

Precast components that are both lightweight and highly durable are examples of structural design innovations that are expected to open up new avenues for creative architecture and robust construction. These patterns point to a bright future for precast concrete in satisfying the changing needs of contemporary buildings.

Building Tomorrow Today: The Sustainable Life Cycle of Precast Concrete

The life cycle analysis of precast concrete demonstrates its many benefits regarding longevity, affordability, and environmental sustainability. Precast concrete technology is positioned to play a larger part in the construction of sustainable and resilient infrastructure as long as innovation propels further advancements in the field, thereby influencing global construction trends.

Integrating Precast Concrete for Visual Appeal in School Structures

In the realm of educational architecture, aesthetics play a vital role in creating inspiring learning environments. Among the myriad of construction materials available, precast concrete stands out for its versatility and potential to enhance visual appeal.

In the realm of educational architecture, aesthetics play a vital role in creating inspiring learning environments. Among the myriad of construction materials available, precast concrete stands out for its versatility and potential to enhance visual appeal. In this blog, we delve into the integration of precast concrete in school structures, exploring its customization options, benefits, and successful applications. Join us as we unravel the art of blending functionality with aesthetics in educational design.

Precast can be used on everything from wall panels to concrete stairs to help match a school’s architectural and aesthetic needs

Understanding Precast Concrete

Precast concrete refers to concrete elements that are manufactured off-site in controlled environments before being transported to the construction site for installation. This construction method involves casting concrete in a reusable mold or form, allowing for precise control over the quality and finish of the final product. Precast concrete components are commonly used in various construction projects, including schools, due to their versatility, durability, and cost-effectiveness. Unlike traditional cast-in-place concrete, precast concrete elements can be produced in a factory setting, where environmental conditions can be carefully monitored, resulting in consistent quality and uniformity. Additionally, precast concrete offers design flexibility, enabling architects and engineers to create intricate shapes, textures, and patterns. With its ability to withstand harsh weather conditions, fire, and impacts, precast concrete is an ideal choice for constructing resilient and long-lasting school structures that prioritize both aesthetics and functionality.

Importance of Visual Appeal in School Structures

The visual appeal of school structures plays a crucial role in creating an environment conducive to learning and development. Aesthetically pleasing architecture can positively impact students' attitudes, behavior, and overall academic performance. Bright, well-designed spaces can foster a sense of pride and ownership among students and staff, promoting a welcoming and inspiring atmosphere. Research has shown that visually stimulating environments can enhance creativity, concentration, and motivation, leading to improved educational outcomes. Additionally, aesthetically pleasing school buildings can contribute to the community's perception of the institution and its values. By investing in attractive and well-maintained facilities, schools demonstrate their commitment to providing a high-quality learning environment for students and staff alike. Therefore, prioritizing visual appeal in school architecture is essential for creating engaging and supportive educational spaces that promote student success and well-being.

Advantages of Integration of Precast Concrete in School Structures

Integrating precast concrete into school structures offers numerous benefits that contribute to the overall quality and longevity of the buildings. One of the primary advantages is the durability and resilience of precast concrete materials, which can withstand harsh weather conditions, impacts, and wear and tear over time. This durability translates to reduced maintenance costs and prolonged lifespan, making it a cost-effective choice for school construction projects. Additionally, precast concrete is highly versatile and can be customized to meet specific design requirements, allowing architects to create visually appealing and functional spaces that enhance the learning environment. The use of precast concrete can expedite construction timelines by minimizing on-site labor and reducing construction waste. With its combination of strength, versatility, and efficiency, integrating precast concrete in school structures ensures that educational facilities are built to last and provide optimal performance for generations to come.

Customization Options for Schools with Precast Concrete

The versatility of precast concrete offers an array of customization options for school structures, allowing architects to bring their design visions to life while meeting the specific needs of educational environments. With precast concrete, schools can achieve a variety of architectural styles, from traditional to contemporary, with ease. Precast panels can be molded into various shapes, textures, and finishes, providing endless possibilities for creating unique facades and interior elements. Additionally, precast concrete allows for the integration of decorative elements, such as patterns, logos, and signage, further enhancing the aesthetic appeal of school buildings. Whether it's creating a striking entranceway, incorporating artistic features, or adapting to site-specific conditions, precast concrete offers the flexibility to tailor school designs to the preferences and requirements of students, staff, and the surrounding community, ultimately contributing to a more engaging and inspiring learning environment.

Precast Is the Right Choice For Schools

Integrating precast concrete in school structures offers a multitude of benefits, from enhanced durability and cost-effectiveness to design flexibility and customization options. By prioritizing visual appeal and functionality, educational institutions can create inspiring learning environments that promote student success and well-being. As schools continue to evolve to meet the needs of future generations, precast concrete stands as a reliable and versatile building material for constructing resilient and aesthetically pleasing educational facilities.

Soundproofing Solutions using Precast Concrete

In the world of construction, one advantage oftentimes put towards the bottom of the list of benefits of using precast is soundproofing. Whether its a commercial structure or a residential building, precast can provide soundproofing so all occupants feel comfortable in their individual spaces.

In the world of construction, one advantage oftentimes put towards the bottom of the list of benefits of using precast is soundproofing. Whether its a commercial structure or a residential building, precast can provide soundproofing so all occupants feel comfortable in their individual spaces. Keep reading to learn how precast is one of the best materials for soundproofing structures of all sizes and types!

Understanding Acoustic Challenges

It's important to understand the acoustic issues that precast concrete can solve. There is a pressing demand for creative acoustic solutions due to common noise-related problems in both residential and business settings. Unwanted noise has been found to have a substantial negative influence on productivity and well-being in addition to upsetting peace of mind for occupants.

The sanctity of dwellings in residential settings can be compromised by noise from neighboring rooms, which lowers quality of life. Loud noises in business settings can impair focus and efficiency of employees, raising stress levels. The precast sector uses innovative solutions that go beyond traditional materials to solve these acoustic problems.

The Science Behind Soundproofing

Precast’s distinct structure and composition function as strong barriers to sound, reducing undesired noise and obstructing the transmission of sound. The industry has developed novel applications by comprehending sound's subtleties and demonstrating precast concrete's effectiveness in producing acoustically superior rooms. These methods make soundproofing more feasible and establishes precast concrete as a fundamental component of building and architectural solutions that aim for superior acoustics.

Benefits of Precast Concrete for Soundproofing

Unmatched in its benefits for soundproofing applications, precast concrete opens up a world of acoustic design. Precast concrete's natural ability to reduce noise fosters peaceful surroundings by separating occupants from outside distractions.

Noise Reduction: Unwanted noise is efficiently reduced and mitigated by precast concrete, making interiors cozier and quieter.

Thermal Insulation: Precast's ability to regulate temperature and provide excellent acoustics also improves overall comfort.

Versatility: Precast concrete can be used for a wide range of purposes, such as wall panels and flooring systems, which allows it to be tailored to meet different soundproofing requirements.

Durability: Precast concrete's natural strength guarantees long-lasting soundproofing solutions that continue to work over time.

Cost-Effectiveness: Precast concrete frequently proves to be a cost-effective option when compared to conventional soundproofing techniques, offering exceptional acoustic performance at an affordable price.

PCI’s Designer Notebook on Acoustics explains architectural acoustics and its use within the industry. It contains information on sound levels, transmission loss, and absorption, as well as acceptable noise criteria and composite walls considerations.

Applications in Residential Spaces

Precast concrete is a game-changer in residential structures, providing unmatched soundproofing options for homes and apartments. Precast concrete finds creative uses in residential soundproofing, redefining comfort and tranquility with wall panels and flooring systems. This focus on residential applications serves to highlight precast concrete's important role in improving the acoustic landscape of residences, offering residents who want silence in their personal havens a comfortable living environment.

Commercial and Industrial Applications

Precast concrete provides a strategic solution in the field of commercial and industrial acoustics, specifically designed to meet the unique soundproofing requirements of these settings. Precast has had its effectiveness proven in industrial environments by demonstrating how soundproofing techniques made of precast concrete lead to increased productivity and better working conditions for employees.

Precast and Soundproofing Go Hand in Hand

It can be easily seen why precast concrete excels as a soundproofing material in modern-day construction. With its inherent ability to dampen sounds, precast is perfect for structures where individual spaces need acoustic separation.

Contact us or one of our producers today to learn how precast can be used on your next project!