Precast Educational Athletic Facilities

Athletic facilities are unique structures in the fact that they need to house thousands of people for major events sometimes multiple times a week while lasting through years of continued use and being exposed to the elements.

Athletic facilities are unique structures in the fact that they need to house thousands of people for major events sometimes multiple times a week while lasting through years of continued use and being exposed to the elements. To achieve this level of capability, athletic facilities need to be built to last using high-quality materials that require little maintenance. Precast is the perfect solution for these facilities to help them stand a lifetime and be prominent structures on school campuses.

Little Maintenance

Precast inherently requires little maintenance once constructed. Structures made from precast can last decades before any kind of maintenance is needed. There are also innovative techniques such as the use of self-cleaning admixtures which keep precast looking new without any additional effort.

High Durability

Precast athletic facilities have several advantages regarding durability. Outside facilities such as stadiums and bleachers will be able to withstand extreme weather events such as snow, rain, high heat, seismic events, and hurricanes without sacrificing their structural stability. Precast also helps these facilities hold up against constant wear and tear from students and event attendees.

Other athletic facilities such as indoor gyms can not only be used for athletic events but also double as storm shelters when built with precast. They can serve as FEMA centers in areas where extreme weather is common and can be used to protect both students and the surrounding community.

Cost-Benefit

Schools often have very tight budgets and are looking to get the most out of their construction projects. Although precast can be slightly more expensive in the short term, in the long term the benefits greatly outweigh the initial cost. Schools will save money in construction costs, maintenance, and the reduced need for renovations. Because precast structures last decades, schools won’t need to consider replacing these structures for many years. Also, precast can help schools be more energy-efficient helping them cut costs on heating and cooling.

Safety

Schools across the country put a lot of value on the safety they can bring to their students. Precast athletic facilities can help schools provide the level of safety they are looking for. Precast is inherently fire resistant and can be built to help stop the spread of fires within the facilities should they happen. Designers can also work with precast to help create safe spaces and restricted lines of sight in the event of unauthorized personnel on campus.

Case Studies

Producers in the PCI Gulf South regions have worked with both K-12 and high educational clients to create athletic facilities that met their unique needs.

LSU Basketball Practice Facility

This project consisted of a 58,960 gross square foot addition to the existing Division 1 University Basketball Arena. Precast was used to create a building form that acted as a natural extension to the futuristic form of the original arena and was used alongside a self-cleaning photocatalytic titanium dioxide admixture, to resist the impact of the adverse climate.

Dudy Noble Field

Built in the 1980s, MSU’s Dudy Noble Field was in need of modern renovations. 99 precast panels covering almost 8,000 SF with architectural precast concrete were used with an acid-etched finish to mimic white limestone.

LSU Tiger Stadium

21 pylons to act as gateways and ticket collection areas for the LSU Tiger Stadium. Precast helped complete the project on a tight project schedule, on a constricted site, with major architectural exposure.

Precast School Renovations and Additions

Precast provides a building solution that K-12 schools can utilize to create modern, low maintenance renovations to existing buildings. Precast structures have an adaptable and versatile design capability that can be blended with existing structures while providing safe and durable spaces for students.

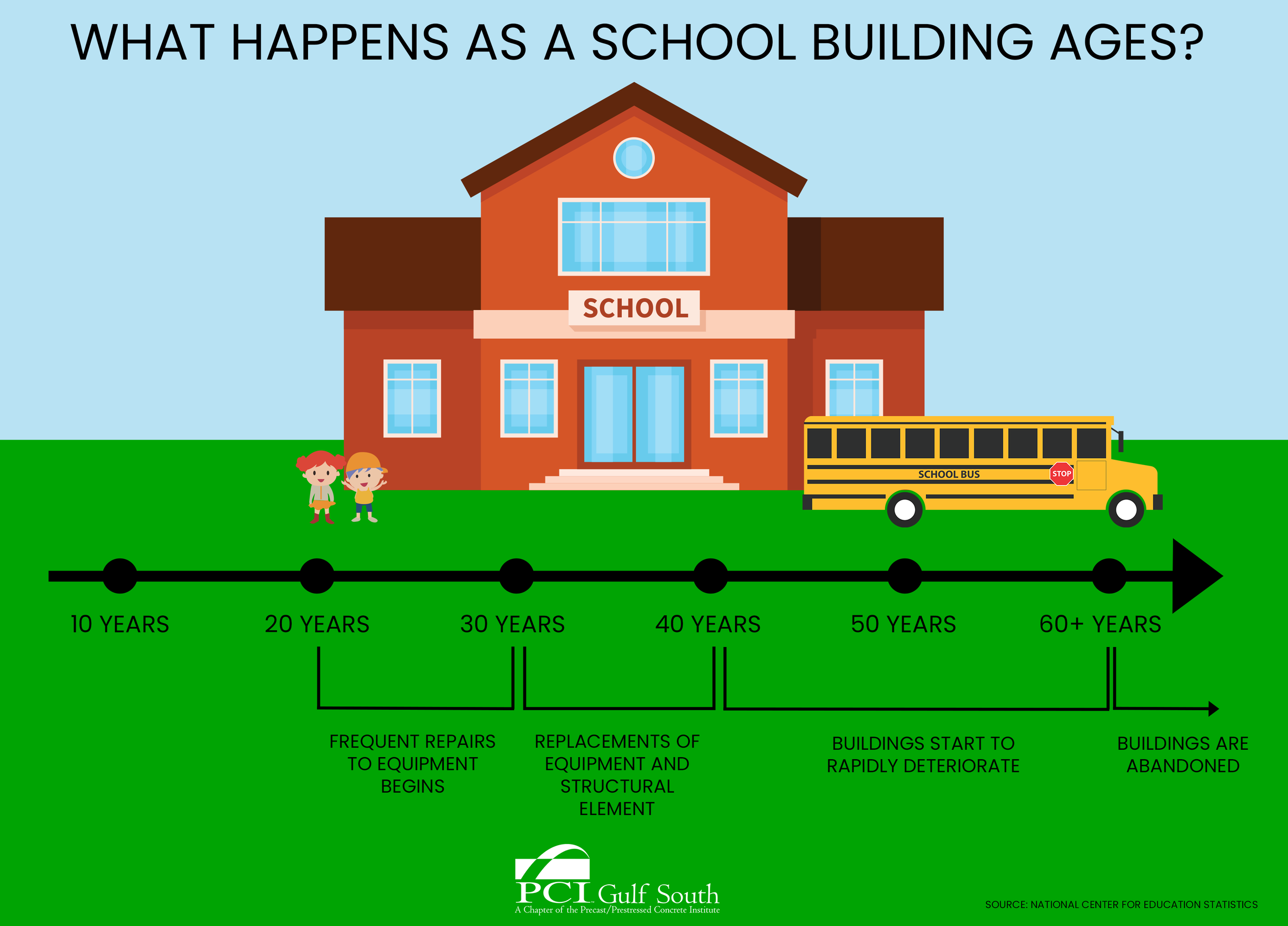

Educational buildings are in constant use and experience heavier activity levels than most buildings. According to available data, the average age of the 99,000 public schools in the United States is 42 years old. When a school building reaches 20 to 30 years in age, frequent repairs to equipment occur. Buildings that reach 30-40 years, begin to require replacement of equipment and structural elements such as roofs. School buildings in the 40 to 60 year range start to rapidly deteriorate and many school buildings are abandoned after 60 years of age.

Based on these statistics, it can be assumed that there are a large number of K-12 school facilities in the United States that are in desperate need of repairs. Not only are these facilities in need of renovations/repair/replacement, but older schools tend to serve a greater number of children in poverty. This correlation is rooted in budget constraints often faced in low-income areas of the country. The 21st Century School Fund projected that schools in 2018 would need to spend on average $196 million to update facilities simply to accommodate new students, a number which has increased over the last few years.

How Can Precast Help

Where does precast fit into this equation and how can precast assist with renovations/repairs/replacements that will serve the student population with minimal maintenance for decades to come?

Precast provides a building solution that K-12 schools can utilize to create modern, low maintenance renovations to existing buildings. Precast structures have an adaptable and versatile design capability that can be blended with existing structures while providing safe and durable spaces for students.

Accelerated Schedules

A major benefit of using precast is the ability of precasters to meet tight project schedules. Oftentimes, schools cannot close during the school year for renovations and are forced to complete construction during breaks or over the summer months. Precast components are manufactured offsite and arrive ready to be erected. Depending on the number of precast components, it can take as little as a few days/weeks to get everything in place, greatly accelerating construction schedules. An additional benefit to the offsite construction of precast is that fewer people and equipment are required on-site.

Match the look of existing materials/styles

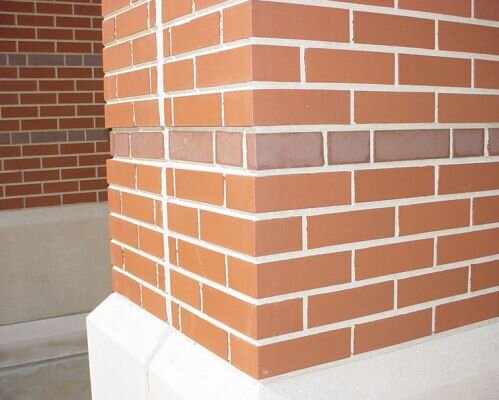

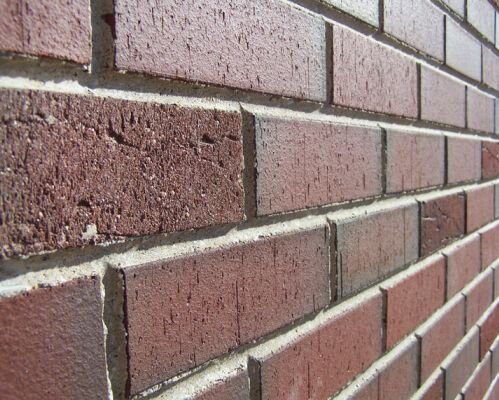

Precast is a versatile building product that offers an array of textures, colors, and styles. Precast has the ability to be matched to existing materials such as stone or brick through the use of brick inlays or specialized formliners. Precasters are able to use forms to make unique designs such as mascots or text. With the versatility of precast, schools have the option to design renovations that match existing architecture or create unique looking additions.

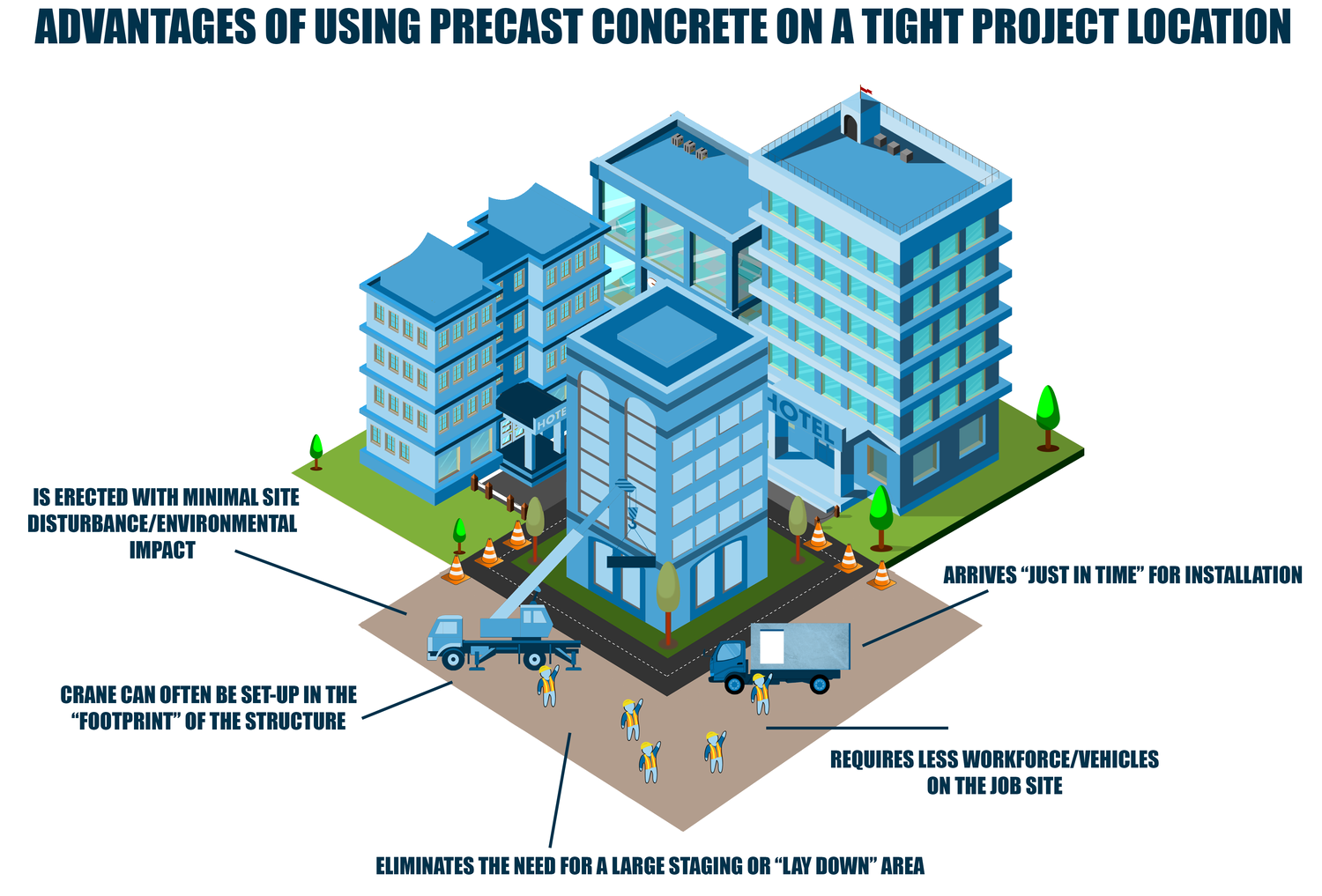

Fit in tight urban or project sites

As previously mentioned, precast components are manufactured offsite in a quality controlled environment by skilled and experienced producers. The offsite process equates to less equipment and personnel on the job site and no delays in production due to inclement weather. This also means that tight project sites, like those often found in urban areas, are no challenge for precast. The precast erection schedule is highly choreographed so components arrive at the site ready to be lifted into place which minimizes truck traffic and the need for a large staging area at the site.

Ascent Summer 2018

PCI published an entire Ascent issue on the role precast plays in K-12 schools and how cutting edge designs meet the schedule and budget needs of schools around the country.

Case Studies

The decision was made in 2011 to preserve the mid-century building with thoughtful additions conveying the significance of its architectural and social merits. The additions utilized precast concrete that saved time and money and resolved a number of design issues.

Summit Country Day School Addition

The solution for the new construction of the school’s addition was precast executed under an IPD-methodology. The existing architecture from 1888 was matched to perfection by a tightly integrated team, erecting a five-story structure and envelope in 21 days.

As school districts continue to explore solutions for aging structures that meet student demands while fitting budget and time constraints, precast is the answer. The versatility, durability, and efficiency of precast “checks off all the boxes” while providing an aesthetically pleasing product that will stand for decades to come.

Architectural Precast & Historic Schools

Historic schools face challenges when they need to expand or adapt. This is where the versatility of precast is the perfect solution!

Architectural Precast Mimics Historic Schools

The US is home to tens of thousands of historic buildings of which thousands are school facilities. One of the oldest school facilities currently in use in the United States is the Boston Latin School is Boston Massachusetts which was created in 1635. Needless to say, schools take pride in their heritage and strive to preserve the historic structures on campus. Historic schools face challenges when they need to expand or adapt. This is where the versatility of precast is the perfect solution!

The Needs of Historical Schools

Historic schools often face challenges of “modernizing” while maintaining the historic appearance. Improving energy usage, creating flexible and adaptable learning spaces and addressing health /safety for occupants is the same for a historic school as it is for a contemporary designed school but with the added need to match the historic aesthetic of the existing structures.

Retaining Historic Individuality

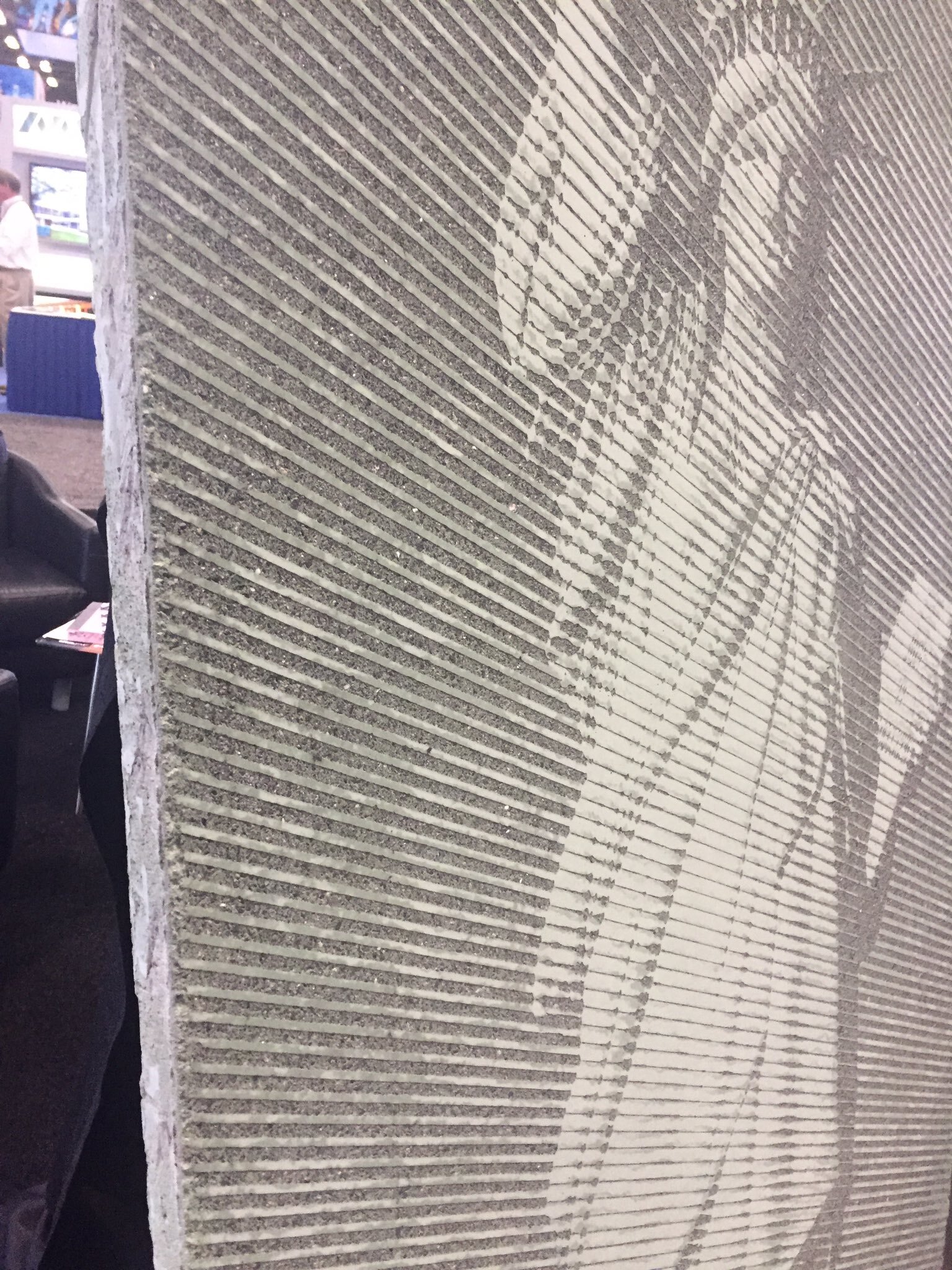

Historic schools showcase the rich history of the campus and typically employ architecture from various time periods. Names, dates and images are often incorporated into the long-standing structures as monuments to the past. The infinite options available with the use of precast concrete allows designers to pick up where history left off, thus maintaining a seamless appearance.

Creating Buildings that Look Exactly Like Original Buildings

Sometimes older buildings have to be replaced. In some cases, schools desire to replicate the original structure with a new one. Precast versatility allows for close duplication of existing structures to include such things as matching color, texture and even brick.

Creating Additions to Blend with Existing Architecture

As school demand grows larger, facilities are forced to grow larger to meet that demand. Historic schools can work with designers to create additions that blend into the existing architecture. The unique challenge for designers is the availability of materials to match existing structures.

How can precast help?

Through the use of pigments, aggregates, acid etching, brick inlays, specialized formliners and more, precast concrete building components are manufactured by highly skilled precast producers to bring a design to life. Whether the design calls for a brand new look or the replication of an existing design, precast has it covered.

Gate Precast provided precast to achieve the look of 100-year old limestone for the St. George Catholic Church, making the new precast components indistinguishable from the original limestone.

Formliners are reusable forms that can recreate patterns such as brick, stone, etc on concrete panels. Read more about the creative freedom of formliners on our blog, Formliners and the Versatility of Precast Concrete.

Below are just a few examples of some of the possibilities!

Case Studies

The Charleston Progressive Academy was built in 1955 and the school wanted to retain its historic identity while providing a modern facility for the students. The decision was made to use precast to help preserve the mid-century building with thoughtful additions.

LSU was looking for an addition to their 1970s basketball arena that would preserve the iconic structure which is located in tight project site. Precast was used to build the new addition in a fraction of the space.

Historical schools face a variety of issues when tackling a new construction project. Adding precast building materials into the design aids in achieving the desired end result while also providing a resilient, versatile, and efficient structure that will stand for years to come.

Schools and Precast in Urban Environments

School facilities constructed with precast require less maintenance in the long term and are smart investments. Boasting numerous advantages, precast limits the need for ongoing facilities spending and allows districts to direct more funds toward the education of the student.

The United States contains over 13,000 school districts that are classified as “urban”. Those districts serve over 49 million students. These school districts have a variety of facilities that require routine maintenance in order to perform efficiently for the student body. As funding and societal issues become more pressing, maintaining a functioning facility is sometimes pushed aside.

School facilities constructed with precast require less maintenance in the long term and are smart investments. Boasting numerous advantages, precast limits the need for ongoing facilities spending and allows districts to direct more funds toward the education of the student.

How does precast help?

Offsite construction

Precast is produced in offsite facilities, thus freeing up space on the job site. Designed and produced in quality controlled environments, schools can rest assured the precast components used to build their facilities have undergone a rigorous inspection.

Quick erection

Because precast is produced offsite, it arrives at the job site ready to be put into place. Precasters understand that schools often require accelerated schedules in order to complete work in between the times when students are present. Precast can be erected in as quickly as a few days depending on the size and complexity of the structure and can be erected in all types of weather.

Blend into surrounding environment

Precast can be designed to match existing or surrounding structures. With a variety of textures, colors, and designs available, precast producers design precast components that help schools blend into urban surroundings or with other buildings on campus.

Less disruption for surround structures

With less personnel and equipment needed to erect precast on site, precast provides less disruptions for surrounding structures and neighbors. Precast is erected quickly meaning loud equipment won’t be on site for long periods of time, thus reducing noise pollution to the surrounding community.

Unique Designs

Schools that wish to add a unique look to their facilities can count on precast to deliver. Precast can be designed in all shapes, sizes, and colors and design details such as text or images can be incorporated into the components through the use of specialized formliners.

Provides Support to Security Efforts

Precast schools provide the advantage of passive security. Through long site lines and secure access points, an impenetrable building that is easier to monitor is achieved.

Along with these specific benefits, precast also offers other benefits to schools such as fire, blast, and storm resistance, as well as mold resistance and superior resiliency and sustainability.

Take a look at some of our additional blogs that illustrate why precast is the right choice for schools.

Case Studies

Charleston Progressive Academy

The Charleston Progressive Academy chose precast to help preserve the historic school which is located in an urban neighborhood and had a tight construction schedule.

Lehigh Valley Charter High School for the Arts

The Lehigh Valley Charter High School used precast to construct its 83,000 SF facility in downtown Bethlehem, PA. The precast components were erected in January during inclement weather in order to meet the August school opening deadline.

While the focus is on improving the lives of students, schools need not be forced to with continual repairs and renovations. Precast, as a primary building material, offers school designers the option that districts need to stretch budget dollars and provide safe, secure and high functioning structures that meet high demands decades to come.

Want more? Check out PCI Gulf South’s technical resources on school facilities on our Institutional webpage.

The Value in a Precast School Structure

The resurgence of precast into the school market started in 2000 when labor shortages placed a crunch on the timelines for school projects. The advancements in precast building products gained a second look of designers because of the lengthy list of advantages precast brings to a project.

The investment in education in the US comes with a phenomenal price tag. A look at both the public and the private school sectors reveals where the bulk of money is spent to support the education of our youth.

Current Environment for Schools

A closer look at the public/private school sector reveals there are roughly 13,506 public school districts in the US with a whopping 130,930 buildings currently in use by school children in K-12. Additionally, there are another 34,576 private schools in the US that serve approximately 25% of the school age population and are mostly religiously affiliated. The median age of the buildings in use are 44 years old and have not undergone a major renovation in the last 12 years.

School budgets are stretched thin each year as taxpayers resist increases and expenses continue to climb. The largest expenditures fall into the categories of:

Maintenance

Infrastructure

Capital Work/Improvements

Staff Salaries/Benefits

Transportation

Utilities

How Can Precast Concrete Play a Role in Easing Budget Woes for School Districts?

The resurgence of precast into the school market started in 2000 when labor shortages placed a crunch on the timelines for school projects. The advancements in precast building products gained a second look of designers because of the lengthy list of advantages precast brings to a project. The desire of school administrators to steer away from traditional 30 student square classrooms located on either side of a main hallway opened the door for the precast community to demonstrate the tremendous versatility and adaptability of precast building systems. With the ability to meet codes in any part of the country, precast components are also the answer to concerns about thermal efficiency, safety from natural disasters, speedy project completion schedules and long-term life cycle cost management issues. Although it’s hard to “teach an old dog a new trick” and schools tend to repeat the same building styles they currently have, specifiers are consistently seeking ways to create learning environments to meet the changing demands of the student population in a sustainable and efficient manner all with a tight grip on the limited funds they have to work with.

Why Is Precast The Right Choice for Schools?

Accelerated Schedules

Offsite manufacturing of precast building systems allows for a high quality product that arrives to the site ready to be installed. The project is not hindered by weather challenges and requires only minimal laborers onsite.

Storm Shelters/Weather Events

Providing a safe learning environment that can pull double duty as a community storm shelter is the beauty of a multi-use precast design. Many districts apply for FEMA funding grants to assist with the cost of new construction. The new construction must adhere to the types of requirements that precast concrete naturally addresses (i.e. IBC wind rating to 250 mph).

LEED/Sustainability

Educational facilities designed to maximize thermal efficiency and lessen environmental impacts have gained momentum with sustainable considerations woven into the design. The PCI Gulf South blog on LEED and precast discusses how precast concrete excels at meeting LEED requirements.

Architectural Precast can match Historic Schools

Oftentimes, districts choose to add an addition to an existing building in lieu of a completely new structure. Through the use of such things as specialized formliners, color and texture options, thin brick inlays, etc precast wall panels can be manufactured to replicate the look of an existing structure for a seamless appearance.

Renovations

The following Ascent issue highlights some of the many ways precast concrete offers school districts the qualities they desire for new projects. From matching historical qualities to budget considerations to increased speed of construction...each project brings a unique set of challenges that precast concrete addresses with efficiency and durability.

Fire Resistance

Precast concrete structures offer premier fire resistance and create an environment that is safer for occupants and safer for first responders in the event a fire does break out. Precast keeps fire compartmentalized and will not burn unlike competing timber building materials.

Security

Schools constructed with precast concrete allow for design options that maximize security by providing long site lines and secure access points. Each design caters to the needs of the school with an impenetrable building product.

Athletic Facilities

Stadiums, training facilities and arenas are areas of extreme use and abuse. Precast concrete systems handle the human element as well as the natural elements and perform exceptionally well in all climates and geographic locations

Urban Environments

School construction in tight urban areas pose challenges to the “traditional” style of building. However, precast components arrive at the site ready to erect with minimal laborers and minimal staging area, thus offering less disruption to existing schools as they remain functional throughout the process.

Read more about precast in urban spaces in our blog below.

Life Cost Analysis

When considering the long-term costs associated with operating a school, the savings realized through the use of a precast building system can be found through lower maintenance costs and reduced heating/cooling costs among other things.

Our blog, Think Long Term Choose Precast Concrete discusses this idea in more detail.

Technical Resources

Ascent offers an invaluable resource for designing educational facilities with precast. Technical information, along with project examples are included here. Click on an article to read more information.

Case Study

The Charleston Progressive Academy reaped the benefits of using precast on their project. With the expertise of Tindall, leading manufacturers of precast concrete building components, the Charleston Progressive Academy had the project completed in under one year, saved tens of thousands of dollars in construction costs, and had their design completed in a tight urban area.

School projects deserve to be designed to make the very best use of the dollars invested in them. Precast concrete systems offer the full package of durability, safety, economy, versatility, adaptability and so much more. This is HOW PRECAST BUILDS.

Precast and Sustainability

So what does LEED have to do with precast? Precast concrete building components possess some of the most inherently environmentally friendly and resource friendly attributes of any building material available.

Building trends evolve over time and one of the more noteworthy changes the industry has seen in recent decades is the creation of the LEED certification rating system. This “badge of honor” is earned through the design of structures that address environmental issues in a mindful manner. The LEED Rating system was developed by the non-profit, non-governmental organization known as the United States Green Building Council (USGBC). The organization has developed this voluntary rating system to aid designers. Oftentimes, public projects will mandate that a structure must attain a specific level of LEED certification but private projects have the option to pursue a rating if desired.

Based on a point system, the more points earned the higher the level achieved and the greater the reward. The points are earned resource-efficient buildings and healthy spaces for occupants.

So what does any of that have to do with precast? Precast concrete building components possess some of the most inherently environmentally friendly and resource friendly attributes of any building material available. The sustainability factor alone of projects constructed with precast well outperforms competing materials.

SUSTAINABILITY

Thermal efficiency: Edge-to-edge, top-to-bottom rigid insulation can be used within a relatively thin wall, providing a high effective R value. The thermal mass of the concrete provides an added benefit by slowing heat transmission through the wall, flattening out temperature swings. Visit the link for further details on precast insulated wall panels

Reduced Life Cycle/Maintenance Costs: Over the life of the structure, precast concrete costs less to maintain and lasts longer than other traditional building materials resulting in less need for repair/replacement. Building a structure that lasts decades with little additional maintenance versus building a structure that requires on-going upkeep makes sense and saves money. Couple this with the integration of recycled materials in the manufacturing process and the savings is even greater.

Energy Savings: Aside from the thermal mass of concrete itself, walls are often insulated with materials such as polystyrene to maximize the R-value. They act as a thick insulated barrier against summer sun and winter cold. This characteristic allows for a smaller investment in HVAC equipment on the front end and eases the load on HVAC systems over the long haul, resulting in lower operating costs.

Durability in Challenging Environments

Whether the issue is hurricanes, flooding or tornadoes, the “tough as nails” properties of precast concrete addresses the issue with an inherent durability unmatched by competing building materials. Dig further into the advantages of precast concrete as a primary building material at both resources at the links below. Sustainability, life-cycle considerations, and environmental product declarations make the case for why pracast is a slam dunk in areas prone to repeated extreme weather challenges.

Current Innovations

Carbon Neutral Concrete

In an attempt to reduce the amount of carbon dioxide that is produced during the production of cement, a key ingredient in concrete, substantial resources have been directed toward solutions to create a more carbon neutral mix.

Concrete Recycling

As further examples of how concrete can be environmentally friendly in the form of a recycled material, visit the following link to learn the five step process for concrete recycling and ways reclaimed concrete is used for such things as underpass abutments, erosion control structures and pipe bedding.

BioInnovation Center

The BioInnovation Center was the first laboratory building in Louisiana to achieve LEED Gold certification as a result of various sustainable features. The sustainable design features include:

An outdoor water feature that also serves as a basin to capture rainwater and AC condensation which provides water to all the building’s landscaping

Careful design which allows for more windows while reducing the solar gain of the facade

Seventy five percent of the building facade provides daylight to illuminate the facility resulting in less energy usage during the day

Building facade includes glaze that provides solar controls to assist with building temperature

Precast concrete building products are sustainable, versatile and durable. Regardless of whether the goal is LEED certification, or simply a building that is going to perform well for decades with minimal maintenance and excellent life cycle costs, precast concrete is a top performer that continues to outshine its competitors in nearly every environmental category over the long haul. Do it right the first time...this is HOW PRECAST BUILDS.

Precast NEXT Beams

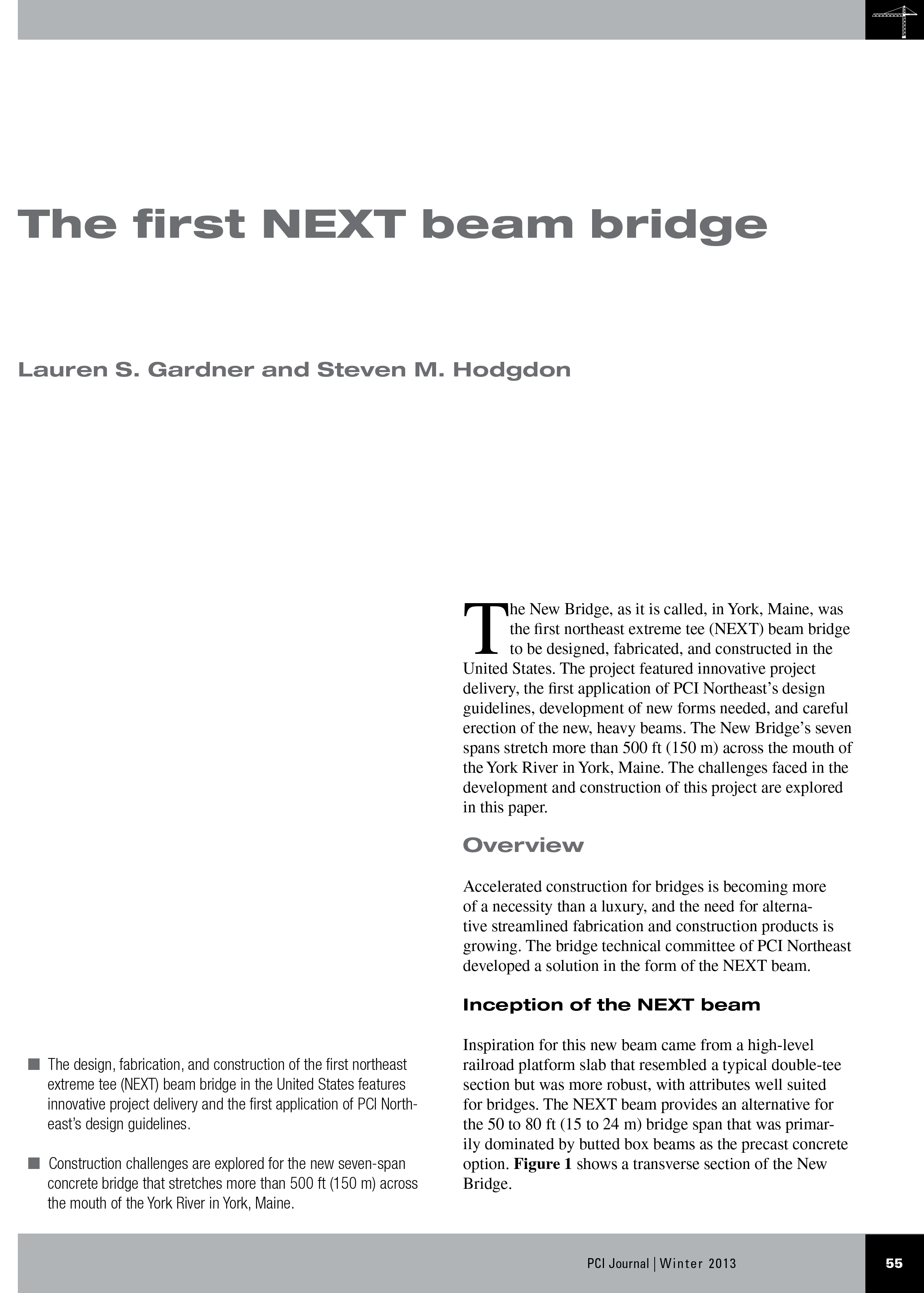

Adding another “weapon to the arsenal” against mounting infrastructure repair/replacement projects across the country, the NEXT Beam was developed by the Northeast State DOT’s in conjunction with consultants and precast concrete producers to serve as a solution to the bridge community’s need for an improved, high functioning beam.

Adding another “weapon to the arsenal” against mounting infrastructure repair/replacement projects across the country, the NEXT Beam was developed by the Northeast State DOT’s in conjunction with consultants and precast concrete producers to serve as a solution to the bridge community’s need for an improved, high functioning beam. These types of beams tackle common bridge construction problems in an efficient, no nonsense manner.

What are NEXT Beams?

The NEXT Beam is a regional standard that was developed by the Northeast State Departments of Transportation and local fabricators. Similar to other standard bridge sections, they are available from multiple fabricators and are not proprietary. In the PCI Gulf South region, Forterra in Pelham, AL is an experienced producer of the NEXT Beam. The development of this new type of beam addressed some recurring issues such as:

The need for shorter spans

Costly expense of adjacent box beams

Accommodation of utilities

Inspection difficulties due to limited side access

Aids in ABC -Accelerated Bridge Construction

All these issues and more were improved with the fabricator-friendly, cost-friendly NEXT Beam that can be produced in variable widths with spans ranging from 40-90 feet.

Technical Resources

Available under the Design Resources tab are PCI Bridge Design Manual specs for NEXT D and NEXT F.

The idea of the NEXT Beam came to life after an observation of an unrelated precast product in a precast concrete manufacturing plant. Read about the chain of events that led to the development of the NEXT Beam.

The first of its kind, The New Bridge (Route 103) in York, Maine was the very first NEXT Beam bridge project completed.

How are they made?

In this time lapse video, Dailey Precast in Vermont shows a highly skilled workforce in a PCI certified precast concrete plant manufacturing a NEXT Beam. The quality controlled process and offsite environment allows for production to be free from common issues, such as weather related interruptions, while maximizing worker safety and efficiency. The completed beam is immediately ready to be trucked to the installation site “just in time” so there is no need for storage at the job site.

What are the benefits of NEXT Beams?

Minimize Labor: Because precast products, such as NEXT Beams, are produced in a plant using reusable forms, the need for manpower is reduced.

Accelerated Schedule: The manufacturing process moves forward without interruption when it occurs at an offsite precast plant. The bridge beams are installed quickly resulting in less disruption to traffic flow in the community.

Cost Saving: Reducing manpower + accelerated work schedule + greatly reduced life cycle costs = significant savings.

Reduced Future Maintenance: Unlike steel bridges or wooden bridges that require ongoing maintenance such as painting or replacement, concrete bridge components are highly durable and function well in extreme weather conditions. For example, the Walnut Lane Bridge north of Philadelphia is the first precast prestressed bridge ever built. It is currently 70+ years old and going strong. Excellent return on investment!

Accelerated Bridge Construction dovetails nicely with the use of precast bridge components such as the NEXT Beam. The ability to minimize time in a work zone by using strategic planning and “ready to install” products speeds the entire process along translating in less disruption for commuters and less opportunity for job site accidents.

Case Studies in PCI Gulf South Region

Phase 1 of the Cribbs Mill Creek Drainage project provided the opportunity for the first NEXT Beam usage in the state of Alabama.

Delivered and erected in just four days, Forterra in Pelham, AL provided sixteen NEXT Beams to span a 280 foot bridge in Decatur, GA.

So it’s said…”necessity is the mother of invention”. The need for a more efficient bridge beam design found its way into the transportation community through the development of the NEXT Beam and it is systematically changing the way bridges are repaired/replaced with an emphasis on cost effectiveness, durability and design flexibility.

Precast Concrete: Making the Most of Tight Spaces

With growing popularity, the construction industry is looking towards the use of precast concrete building components to solve or lessen the issues of working within a small area. Precast concrete as a primary building material for a project brings advantages no other material can match.

There are a lot of reasons why it’s sometimes necessary to squeeze a structure into a tight space. Given the choice, designers and contractors would not choose to be faced with constructing a project in close confines. However, there are times when a choice of locations is not an option and the challenge must be tackled. Some reasons for building in a cramped location might include:

Rebuild/replace a demolished structure in original location

Expansion of an existing structure

Prime location for business/industry/tourism etc

With growing popularity, the construction industry is looking towards the use of precast concrete building components to solve or lessen the issues of working within a small area. Precast concrete as a primary building material for a project brings advantages no other material can match.

Along with the favorable manner in which precast concrete meets the needs of a small project area are some well known benefits of offsite manufacturing such as:

Produced in a quality controlled/quality inspected environment

Not at the mercy of weather related delays/cancellations

Consistent, high quality is achieved with each piece

Trucked to the jobsite when needed

In the PCI Gulf South region and other regions across the US, PCI certified producers know how to work in tight urban spaces while still providing a quality product to our clients. Below are a few examples of completed projects there were erected in confined spaces.

WWII Museum in Downtown New Orleans

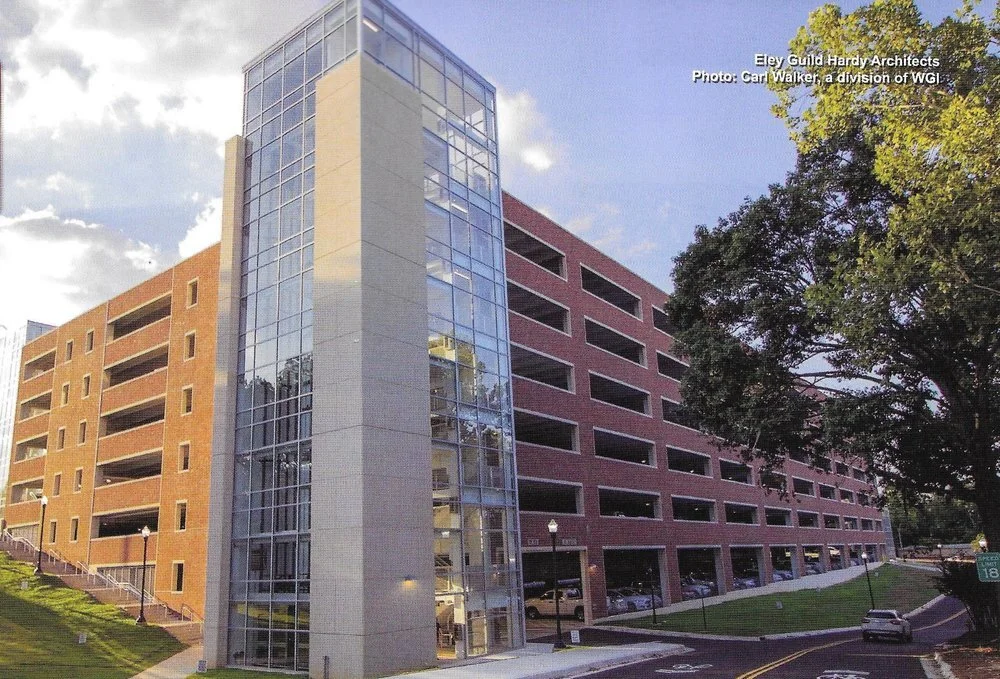

University of Mississippi North Parking Structure

Campbell Sports Complex at Columbia University

The difficulty of building in a confined space cannot be minimized regardless of what building material is selected, but precast concrete products are particularly versatile and flexible. With careful planning/scheduling/sequencing/crane coordination, incredible structures have been created in some extremely challenging spaces using PCI certified precast concrete building materials.

Precast Connections

In the erection of a precast structure, connections are the “glue” that keeps it all together. As such, there is a vast array of connections available to meet the individual requirements of the project.

Precast Connections: The "glue" that holds it all together

In the erection of a precast structure, connections are the “glue” that keeps it all together. As such, there is a vast array of connections available to meet the individual requirements of the project. The transfer of loads, restraint of movement and creation of stability is the role of connections.

Connection Design Considerations

Strength

A connection must have the strength to avoid failure during its lifetime.

Ductility

The ability of a connection to undergo relatively large deformations without failure.

Volume

Change Accommodation Restraint of movement due to creep, shrinkage, and temperature change can cause large stresses in precast concrete components and their connections. It is better to design the connection to allow some movement, which will relieve the build-up of these stresses.

Durability

When the connection is exposed to weather or used in a corrosive environment, steel elements should be adequately covered by concrete, painted, epoxy-coated, or galvanized. Stainless steel may also be used, however, the added cost should be considered carefully.

Constructability

The following reflects only some of the items that should be considered when designing connections:

Standardize connection types

Avoid reinforcement and hardware congestion

Avoid penetration of forms

Reduce post-stripping work

Consider clearances and tolerances of connection materials

Avoid non-standard product and erection tolerances

Plan for the shortest-possible crane hook-up time

Provide for field adjustments

Provide accessibility

Determine if special inspection is required per the applicable code for the material and the welding process

Provide as direct a load path as possible for the transfer of the load

Fire Resistance

Connections, which could jeopardize the structure's stability if weakened by high temperatures from a fire, should be protected to the same degree as the components that they connect.

Aesthetics

For connections that are exposed to view in the final structure, the designer should incorporate a visually pleasing final product.

Seismic Requirements

Structures and/or components that must be designed for seismic loads may require special consideration. Consultation with a structural engineer with experience in seismic design is recommended.

Tolerances

The designer must realize that normal allowable fabrication, erection, and interfacing tolerances preclude the possibility of a perfect fit in the field

Connection Materials

Headed Concrete Anchors (studs) are round bars with an integral head. These are typically welded to plates to provide anchorage to the plate.

Steel Shapes including wide flanges, structural tubes, channels, plates, and angles.

Reinforcing Bars are typically welded to steel sections to provide anchorage to the steel.

Reinforcing Bar Couplers are typically proprietary devices for connecting reinforcing bars at a joint. Precast producers of these services can provide technical information.

Deformed Bar Anchors are similar in configuration to deformed reinforcing bars and are welded to steel shapes to provide anchorage similar to headed concrete anchors.

Bolts and Threaded Connectors are used in many precast concrete connections. Use of ASTM A36 or A307 bolts is typical. Use of high-strength ASTM A325 and A490 is usually not required.

Specialty Inserts are available from many precast producers of these devices. They include standard threaded inserts, coil threaded inserts, and slotted inserts that provide for tolerances and field adjustment.

Bearing Pads are used predominantly for structural applications to support beams, double tees, and similar components. Use of random fiber oriented bearing pads (ROF) is recommended.

Shims can be hard plastic or steel and are often used to provide adjustment to align a precast concrete component for elevation or horizontal alignment.

Looking to learn more about connections? Try the PCI resources below!

Types of Connections

Click on any of the connection type graphics below to get a better look!

Structural Connection Types

Cladding Connection Types

The structural connections are generally used in structures such as parking garages, office buildings and warehouses where panels sit on a footing whereas, the cladding type of connections are used to attach the outside cladding to the underlying structural frame that could be made of various materials ( ie. steel)

Connection Examples

Pic #1 is a Double Tee to Corbel

Pic #2 is a Spandrel Beam to Column

Pic #3 is a Panel to Panel Connection

The role connections play in the erection of a precast concrete structure are key to its strength and durability. Producers and engineers work diligently to employ connections that best fit with the project needs to meet and/or exceed all applicable codes.

For further information please refer to www.pci.org.

Precast Curing Systems

Operating a profitable precast concrete plant hinges on the ability to move product through the facility in a timely manner.

Photo via Civil Engineers Forum

Operating a profitable precast concrete plant hinges on the ability to move product through the facility in a timely manner. A key part of the precast manufacturing process that has a direct relationship to profit is being able to “turn the beds” as often as possible. The phrase “turn the beds” refers to removing completed product so that the next batch of product can be started.The speed at which the producer can engage in this repetitive cycle is what allows them to be competitive in the market. In order to do this, the precaster must attain 75% of the ultimate 28 day designed compressive strength of the concrete within 12 to 15 hours from final placement of the precast product.This 75 % is the level a precast piece needs to attain in order to be stripped and handled.

Air Curing

The most basic and least expensive technique is air curing. This involves simply allowing the concrete to dry naturally without any additional treatments/actions. Most producers will not use this type of curing due to the development of surface cracks and increased strength will not occur earlier in the cycle.

Adding Additional Cement

Adding additional cement to the mix to obtain a higher strength earlier in the curing process. Some plants also change the type of cement used from Type I/II to a Type III to achieve the advanced strength needed to “strip” or remove the product in the 12 to 15 hour time frame. The drawback of this method is an increase in price, as cement is one of the more expensive ingredients in the concrete mix.

Using Chemical Additives

The next curing option is the use of chemical additives, primarily, the use of accelerators. Accelerators increase the rate of hydration, which speeds up the set time, thus kickstarting the curing cycle earlier. The major drawback to accelerators is the increased cost. Accelerators require a seasoned technician with experience and knowledge of the process.

Curing Compounds

Curing compounds are also options when applied after finishing and used in conjunction with curing blankets to trap moisture and elevate the internal temperature of the product...allowing for a greater rate of hydration speeds up the curing cycle and increases the strength earlier. A typical drycast product uses this type of system.

Water Curing

The last two types of systems are active systems that require equipment and procedures. Water curing is a system by which burlap and soaker hoses are used for a period of time “to soak” the concrete, thus keeping it moist and trapping internal moisture at the optimal level for hydration. This system is also used in hot climates to keep the internal curing temperature from reaching levels that are not conducive to good curing practices. This system is used on DOT projects/products.

Water and Steam Curing

Finally, a commonly employed technique is a type of water/steam curing system that allows a precast piece to be stripped within the 12-15 hour time. In this case, low pressure steam is introduced into a controlled environment, such as an enclosed structure (or temporary structure like a tarp), at elevated temperatures for a predetermined time and then allowed to be cooled at a controlled rate. This provides a number of advantages to the curing cycle, such as maintaining relative humidity between 75%-90%. The greatest advantage to this system is the degree of control a producer has with the concrete curing cycle. Many producers customize the steam curing system for changes in the seasons or plant production cycles.

In conclusion, properly cured concrete will, in most cases, out perform design parameters and allow a properly designed structure to increase its life cycle and ultimately be a sustainable and resilient structure far into the future.

References: NPCA Tech Notes, Curing Wet-cast precast concrete

Precast in Universities and PCI Studios

University level education of future designers and engineers is crucial to the continued growth of the precast concrete market. As future industry professionals become masters of their trade, the investment that has been made in education at the university level is well worth it.

University level education of future designers and engineers is crucial to the continued growth of the precast concrete market. As future industry professionals become masters of their trade, the investment that has been made in education at the university level is well worth it.

Benefits of Teaching Precast in School

Young Engineers/Architects enter the workforce with knowledge on precast

Designing with precast concrete has not typically been a mainstream practice. Although precast concrete is one of the most versatile building products available, the precast industry has not marketed the product to its full potential. The idea of university level education is to plant the seeds of precast in a budding student’s bag of tricks for future reference.

Young Engineers/Architects can bring fresh design solutions to the construction industry

As students graduate from their programs and enter the workforce, they carry with them fresh ideas that perhaps their seasoned colleagues are unfamiliar with. By introducing and sharing perspective, young professionals help to offer design solutions that may not have been previously considered.

Young Engineers/Architects will be familiar with precast and can easily educate clients on the benefits

The idea of sharing fresh ideas and options with coworkers carries over to perspective owners/clients as well. Providing an array of design options to owners on the front end of a project is always a welcome sales tactic.

Young Engineers/Architects will be challenged to think how to use precast in unique ways

Because precast concrete offers a tremendous amount of creative freedom, it is an especially appealing and exciting building material to design with. The options and variations available, give each project unique possibilities. Engineers/architects comfortable with the uses and functions of precast concrete components strive for new options instead of repeating common designs.

PCI Foundation

The PCI Foundation’s sponsored competition known as “Project Precast” is held annually and involves college level students creating a precast concrete design on a compressed two day schedule. The 2019 winner of the contest was Team Tindall with a winning horse barn design.

Formed in 2007, the PCI Foundation has worked tirelessly to provide curriculum grants to schools of architecture, engineering and construction management. With the goal of building relationships between the academic community and the precast concrete industry, the Foundation raises and disseminates funds to advance the knowledge and use of precast concrete.

Along with instructional visits from precast concrete industry professionals, manufacturing plant tours, and reference/teaching materials, the PCI Foundation offers a four year grant program to universities in the form of a “studio” that allows professors to work through a proposed problem utilizing precast as a solution. The studio grant awardees are selected by a board of precast industry partners annually.

PCI Studios

The process of being awarded a studio requires several steps on the part of the professor vying for the grant. The submission of a winning idea/proposal and attendance at a Foundation workshop for professors is mandatory. Proposals are evaluated using many criteria and often include partnership with other professional associations, producers and associate members of PCI.

The PCI Foundation offers a free webinar entitled How to Partner with a University in a PCI Foundation Grant. This comprehensive webinar provides all the pertinent information necessary to fully understand the process of partnering.

Tulane Studio

The first studio awarded in the Gulf South region was at Tulane School in New Orleans, LA. The four-year studio is led by faculty members Charles Jones, RA and Kentaro Tsubaki and focuses on urban water infrastructure challenges. The students are keenly aware of the challenges areas such as New Orleans repeatedly face and they are working to design solutions using precast concrete as a building material. Members of PCI Gulf South such as Gate Precast, Tindall Precast, Boykin Brothers Precast and US Formliner have been working side-by-side with Tulane to meet their needs in the form of materials, funds, tours, and industry advice.

A full description of Tulane’s progress with the studio and the work the students have been involved in as available in the Summer 2019 edition of Ascent magazine.

New PCI Gulf South Studios

Fall 2019 brought the awarding of two more studios to the Gulf South region. Both Mississippi State University and the University of Alabama join the elite group of universities nationwide who won four-year grants to put their proposals into action. PCI Gulf South producer members and associate members look forward to working with the students as they expand their knowledge and challenge themselves to find new and innovative ways to use precast concrete to solve problems. Supporting MSU and UA are Gate Precast, Forterra, Tindall Corp, Jackson Precast, PTAC, US Formliner, M2 Solutions, as well as the Mississippi AIA who will be taking a role in the studio at MU.

The advancement of any industry happens when people work together and share their knowledge and experiences. The precast industry recognizes and values the fresh and insightful ideas of university students and will continue to work in partnership with them to advance the use of precast concrete in the building community.