The Versatility of Precast Concrete in School Renovations

School building construction using precast concrete is undoubtedly becoming more popular. Over the past few decades, there has been a significant increase in the use of precast concrete components for various public buildings. This trend has a number of causes, and administrators and builders who are designing new schools can learn a lot from it.

School building construction using precast concrete is undoubtedly becoming more popular. Over the past few decades, there has been a significant increase in the use of precast concrete components for various public buildings. This trend has a number of causes, and administrators and builders who are designing new schools can learn a lot from it.

Trend Towards Precast Use in Schools

Teachers and students worry about how they are influencing the world of tomorrow, which they know will be passed down to the next generation. The use of precast concrete materials in the construction of new schools is influenced by a number of important factors. The following are common explanations for the move toward precast concrete school buildings:

Time Savings

Saving Money

Efficiency

Safety

Versatility

Quality Control

Benefits of Precast Concrete For School Projects

When designing schools, architects and engineers must overcome unique design obstacles and strike a balance between sustainability, comfort, and safety while providing outstanding environments for staff and students. Precast concrete school buildings offer superior, creative solutions that satisfy these design needs and more. The end result is a learning environment that genuinely promotes education and well-being.

It is commonly known that environments with materials that regulate temperature, humidity, and air quality are ideal for learning. Acoustics and aesthetics are equally important. The best attention and knowledge retention are made possible in a peaceful and pleasant environment, which is beneficial for effective learning.

Another important consideration in school architecture is lighting. Students have been shown to benefit from natural light, which is why school owners largely request this design feature. Expansive glass windows and open areas are the best methods to optimize natural light, and they can be readily accomplished with wide spans of precast wall panels, beams, and columns. Like all precast concrete components, architectural precast panels provide an easy-to-use and efficient way to improve learning settings.

School boards and districts give equal weight to cost-effectiveness and safety when making decisions. In-tune, administrators have seen the increasing use of precast concrete by top school officials and understand its benefits. Due to its effective use in school projects, precast concrete is now the most popular option for contemporary school construction.

Life Cycle, Sustainability, and Cost Savings of Precast for School Projects

Both for long-term operational requirements and capital construction budgets, precast concrete components offer numerous cost savings. Savings include expenses that are frequently concealed in the overall construction budget and produce benefits that last for the duration of the building's life.

Precast concrete is manufactured in regulated off-site facilities, guaranteeing excellent quality and reducing the need for on-site inspections. Construction timescales are greatly reduced by using integrated precast components, which remove months off the timetable. This method lowers overall project risk, contractor overhead, and financial bond durations. It also removes expenses related to waste management, site storage, and masonry scaffolding.

Because precast concrete is naturally resistant to fire and storms, it can lower insurance premiums. Integrating several components into a single panelized system also provides environmental friendliness and economic savings. There is a significant benefit when the savings from the construction and long-term operation budgets are combined. In comparison to a masonry building, a precast concrete system is predicted to save over seven percent of the total costs over the course of the school's existence.

Schools and Project Teams Can Benefits From Building With Precast Concrete

Precast is unmatched in its ability for adaptability which makes it the perfect construction materials for school renovations and new constructions. It meets the needs of modern educational facilities which includes a focus on sustainability and safety. Precast can also shorten construction schedules which are often short due to the school year and can help school boards cut expenses. Schools can adapt to the needs of both staff and students because of precast concrete's ability to blend in seamlessly with existing structures and provide creative design options. School districts can invest in long-lasting, cost-effective, and future-ready solutions by selecting precast concrete.

Precast Concrete Architectural Diversity in the Gulf South

The architecture of the Gulf South is a dynamic fusion of styles with a long, rich history of various influences and environmental considerations. Because of the region's architectural diversity, robust and adaptable building materials are required to keep the buildings standing for decades. The perfect answer for meeting these various architectural needs is precast concrete, which allows architects and builders to alter designs to suit the unique structural, aesthetic, and sustainability requirements of the Gulf South.

The architecture of the Gulf South is a dynamic fusion of styles with a long, rich history of various influences and environmental considerations. Because of the region's architectural diversity, robust and adaptable building materials are required to keep the buildings standing for decades. The perfect answer for meeting these various architectural needs is precast concrete, which allows architects and builders to alter designs to suit the unique structural, aesthetic, and sustainability requirements of the Gulf South.

Understanding the Architectural Diversity of the Gulf South

The Gulf South is known for its rich architectural diversity and coastal aesthetic styles that create a unique regional identity:

French Influence: French colonial design introduced elements like high ceilings, broad verandas, and intricate ironwork, which helped adapt structures to the humid Gulf South climate.

Spanish Influence: Spanish architecture contributed courtyards, arched doorways, and stucco walls, adding both elegance and functional cooling to buildings in the region.

Creole Influence: Creole styles blended French, Spanish, and African elements, resulting in unique features like colorful facades, open floor plans, and decorative balconies.

Antebellum Influence: Antebellum architecture, prevalent in the pre-Civil War South, emphasized grand columns, expansive porches, and symmetry, reflecting both Greek Revival and neoclassical styles.

The region's fusion of innovation and tradition is reflected in urban projects, new seaside designs, and historic residences. Materials that can accommodate both traditional and modern aesthetics are required for this architectural blend. Precast concrete offers the adaptability to satisfy these diverse design requirements.

Priorities including robustness, durability, and aesthetic appeal are crucial in Gulf South architecture in order to endure the region's particular climate problems. Precast concrete satisfies these requirements by providing durability and adaptability, guaranteeing that buildings are both aesthetically pleasing and long-lasting.

Customization in Precast Concrete for Regional Needs

When it comes to satisfying the distinct structural requirements and aesthetic preferences of the Gulf South, precast concrete provides unmatched versatility. In addition to improving longevity and resilience against humidity, hurricanes, and salt exposure, customization possibilities allow designers to express the region's rich architectural tradition through changes in thickness, color, and texture. Precast panels can mix in perfectly with historical settings by simulating conventional materials like stone or brick. Precast components offer long-term dependability by including weather-resistant coatings and high-performance reinforcements. Precast design's adaptability guarantees that structures satisfy Gulf South communities' functional requirements in addition to their aesthetic standards.

Design Flexibility in Precast Concrete for Aesthetic Appeal

Because of the design versatility of precast concrete, architects may create unique aesthetics that complement the variety of architectural styles seen in the Gulf South. Precast can be shaped, colored, and textured to produce contemporary visual statements or to evoke local historical influences. Each project can be customized to blend in with its surroundings by choosing from alternatives for stone-like surfaces, smooth finishes, or complex detailing. Because of its adaptability, precast is perfect for creating both classic elegance and cutting-edge designs, improving the aesthetic impact of public, commercial, and residential areas while maintaining architectural integrity.

Because precast concrete offers structural modifications to survive high winds, humidity, and salt exposure—all of which are typical in coastal areas—it is perfect for the Gulf South's urban and coastal surroundings. Its innate strength and durability lower maintenance requirements and increase building longevity, which is crucial in metropolitan areas dealing with environmental issues and growing densities. Architects may guarantee safer, more resilient constructions for both residential and commercial areas by tailoring precast elements to these requirements.

Precast concrete sustainability promotes environmentally sustainable construction in the Gulf South. Precast lowers the carbon impact of construction by maximizing manufacturing and utilizing locally sourced resources. Longer-lasting buildings reduce waste and resource consumption because of the material's durability and energy-efficient production process. Precast is a good option for architects who prioritize ecologically friendly architecture in the area because it may also integrate recycled materials, which improves sustainability.

Precast Was Made For the Architectural Diversity of the Gulf South

Precast concrete may be tailored to the architectural diversity of the Gulf South to create creative, long-lasting, and aesthetically pleasing structures that capture the region's distinct environmental and cultural landscape. Architects can create structures that satisfy both functional and aesthetic requirements by embracing architectural flexibility, structural modifications, and sustainable methods. Precast concrete is still a great material for the Gulf South's continued expansion since it is long-lasting, adaptable, and environmentally friendly, all of which complement the area's architectural legacy and changing priorities. Precast gives designers and builders a strong tool to construct classic spaces that respect the unique character of the Gulf South while anticipating future needs.

Precast Concrete's Importance in the Gulf South's Disaster-Prone Regions

The Gulf South is renowned for its breathtaking scenery, but nature also poses a persistent threat to the region. This area experiences frequent extreme weather, such as hurricanes, flooding, and strong winds.

Safeguarding these communities requires more than just putting a plan in place; it also calls for strengthening existing structures.

The Gulf South is renowned for its breathtaking scenery, but nature also poses a persistent threat to the region. This area experiences frequent extreme weather, such as hurricanes, flooding, and strong winds.

Safeguarding these communities requires more than just putting a plan in place; it also calls for strengthening existing structures. Fortifying this disaster-prone location with precast concrete can help ensure both safety and durability in the face of nature's difficulties. Precast concrete is a durable and long-lasting solution.

Not only is storm survival important here, but building infrastructure that can resist storms in its entirety is vital as well.

Understanding the Gulf South's Disaster-Prone Nature

Strong hurricanes, ongoing flooding, and catastrophic storm surges are commonplace in the Gulf South. Alongside these disasters, there are often strong winds and flying debris that cause havoc on homes, businesses, and public infrastructure. Because storm severity has increased over the past few decades, communities now need to prepare for more severe weather events.

These climatic catastrophes have the potential to be extremely destructive, endangering human life. Businesses are forced to close, homes are regularly destroyed, and vital infrastructure—like community centers and hospitals—can become unusable. The incalculable financial and psychological cost underscores the pressing need for resilient infrastructure.

It is essential to construct buildings that can survive the severe weather in the Gulf South area in order to safeguard communities and guarantee safety. The goal of resilient infrastructure is to design structures and areas that can continue to be used long after a calamity has passed, not only to weather a storm. In the face of natural disasters, precast concrete provides the strength and resilience required to safeguard communities in the Gulf South.

The Role of Precast Concrete in Disaster-Resilient Construction

Strength and Durability

When it comes to resisting the effects of nature, precast concrete is an incredible material. Because of its intrinsic strength, structures can withstand storm surges, strong winds, and debris impact. Even during severe weather conditions like hurricanes, buildings made of precast concrete have a considerably higher chance of remaining intact and standing.

Water and Mold Resistance

In the Gulf South, flooding is a persistent risk, and water damage can completely destroy structures. Precast concrete is extremely resilient to mold development and water damage. Because of this, it's the perfect option for flood-prone areas, minimizing damage and lowering health hazards related to mold growth following water exposure.

Fire Resistance

While most people don't consider fires when severe weather strikes, they might occur as a result of downed power lines or damaged infrastructure. Precast concrete's ability to withstand fire offers an extra layer of security, preserving buildings and giving emergency responders plenty of time to contain the problem. For community centers or shelters that accommodate large numbers of people, this extra safety might be essential.

Long-Term Benefits of Precast for Gulf South Communities

Cost-Efficiency Over Time: Precast concrete may need a larger initial investment than other materials, but over time, its advantages make it a more affordable option. Because of its longevity and fire and water resistance, precast concrete can withstand more damage before needing expensive reconstruction after a disaster.

Environmental Sustainability: Precast concrete is a sustainable material in addition to being strong. Because precast is more durable, there is less need for maintenance every so often, resulting in less waste. More ecologically friendly production techniques are being used to make many precast components, which aids in development and reconstruction projects reaching their sustainability goals.

Supporting Economic Resilience: Stability in the economy is closely linked to resilient infrastructure. Communities can minimize the impact on local economies and keep companies open during disasters by employing precast concrete to minimize downtime. Critical services can only continue with a robust and dependable infrastructure, which contributes to the general resilience of Gulf South towns.

Case Studies: Precast Concrete Success Stories in the Gulf South

Hurricane-Proof Buildings

Precast concrete has previously proven useful in the Gulf South. Certain precast concrete structures, like the Cameron Parish School Warehouses, withstood recent hurricanes and are still standing and functional in spite of the considerable damage suffered by nearby buildings. These hurricane-resistant buildings show how using the right materials can improve community safety.

Flood-Resistant Infrastructure

Precast concrete has been utilized to construct long-lasting flood barriers, levees, and flood-resistant structures in flood-prone areas. Through the effective mitigation of flood damage and protection of vital infrastructure, these projects have made communities resilient to rising water levels.

One example of this is the precast Biloxi Beach Outfalls, which replaced the existing metal piping to help carry more stormwater runoff from the City into the sound.

Community Centers and Shelters

Community centers and shelters are vital resources for locals living in disaster-prone areas. A safe haven for people to wait out hurricanes has been made available by certain precast concrete community facilities in the Gulf South.

The Robert J. Curry Public Safety Center replaced the Gulf Police Station destroyed by Hurricane Katrina with a precast structure designed to withstand 200 mph winds and be self-sustaining for up to 36 hours without power so it could act as a hurricane shelter.

These types of buildings serve as an example of how precast concrete can improve community safety.

The Smart Choice for Disaster-Resilient Construction: Precast Concrete in the Gulf South

Precast concrete plays a critical role in enhancing community safety and resilience in the Gulf South. Precast concrete is a favored building material in disaster-prone areas because of its water resistance, strength, durability, and long-term cost-effectiveness. If we invest in precast concrete infrastructure today, future generations can live in communities that are safer and more secure.

So if it's time to get started on your next project, think about using precast concrete. Together, let's construct a Gulf South that is safer and more beautiful!

Disaster Recovery: Precast Concrete's Impact on Infrastructure in the Gulf South

Disasters are an awful reality in the Gulf South, where hurricanes, floods, and other natural disasters constantly threaten infrastructure. In the face of these difficulties, the use of durable building materials, such as precast concrete, becomes essential.

Disasters are an awful reality in the Gulf South, where hurricanes, floods, and other natural disasters constantly threaten infrastructure. In the face of these difficulties, the use of durable building materials, such as precast concrete, becomes essential.

Disaster Recovery Challenges in the Gulf South

The Gulf South region has particular difficulties in recovering from disasters. Regular dangers that can seriously harm infrastructure, including roads, bridges, and buildings, include hurricanes, floods, and storm surges. These calamities frequently surpass the speed and scope of conventional construction techniques, delaying relief operations and raising expenses.

Because of its geographic location, the Gulf South is vulnerable to extreme weather, which makes strong and long-lasting building materials necessary. High humidity, salty conditions, and possible seismic activity are some of the environmental challenges that infrastructure projects in this area must overcome. These challenges make the disaster recovery process more difficult.

Role of Precast Concrete in Disaster Recovery

In the Gulf South, precast concrete is essential to disaster recovery efforts. Because of its innate strength and resilience, it is the material of choice for reconstructing infrastructure following catastrophic disasters. Reconstruction can be expedited by using precast concrete components, such as beams, columns, and panels, which can be produced off-site and swiftly delivered to the catastrophe site. Particularly in regions vulnerable to regular severe weather like hurricanes and floods, this efficiency is essential to addressing the pressing need for restored infrastructure.

Precast concrete is the best material for buildings and structures in disaster-prone areas because of its resilience to strong winds and storms. Precast concrete's strength and resilience lessen the possibility of structural damage during disasters, allowing for the safe occupancy of structures shortly after the weather has passed. This helps communities impacted by disasters feel normal while hastening the healing process.

Benefits of Using Precast Concrete in Infrastructure Projects

In the Gulf South, precast concrete has many benefits for infrastructure projects. It is an exceptional option for meeting the specific infrastructure requirements of the area due to its adaptability, resilience, and speed of construction.

Accelerated Construction: By enabling off-site manufacturing, precast components can be assembled on-site more quickly, greatly cutting down on construction time.

Durability and Resilience: The long-term structural integrity of precast concrete is guaranteed by its exceptional resistance to weathering, wear, and natural disasters.

Cost-Effectiveness: Precast concrete is a more affordable option over time due to its shorter construction time and lower maintenance costs, even though its initial prices may be slightly higher.

Customization: Precast concrete offers versatility in design and function and can be made to meet individual project requirements.

Sustainability: By reducing waste, energy use, and environmental effects, precast concrete usage supports environmentally friendly building methods.

Quality Control: Controlled factory conditions are used to make precast components, guaranteeing uniform quality and accuracy.

Precast concrete offers advantages that go beyond its ease of use in construction. Its durability to the harsh climate of the Gulf South, cost-effectiveness, sustainability, and quality control procedures make it a vital component of contemporary infrastructure development, greatly enhancing the resilience and economic growth of the area.

Rebuilding U.S. 90 Bridge after Hurricane Katrina with Precast Concrete

Following the destruction of the Biloxi Bay Bridge by Hurricane Katrina in 2005, a critical reconstruction effort was initiated to reconnect Biloxi and Ocean Springs. The new bridge, designed to withstand a Category 5 hurricane, included innovative features and utilized precast concrete extensively.

Challenges and Solutions:

Debris Management: Post-hurricane debris posed challenges during construction. The design team strategized to work around the debris, allowing early installation of precast components and ensuring project continuity.

Industry Surge: The surge in post-hurricane construction led to potential delays. To mitigate this, the design limited specialty precast components, enabling more producers to participate and ensuring timely delivery.

Complex Design Needs: The bridge's varied geometry and load conditions required an economical yet effective design. An assembly-line approach minimized formwork and equipment requirements, streamlining construction.

The successful reconstruction of the Biloxi Bay Bridge stands as a testament to the resilience and ingenuity of precast concrete solutions in post-disaster scenarios, offering a durable and efficient infrastructure that withstands the test of time and extreme weather conditions.

Weathering the Storm: Precast Concrete's Role in Gulf South Resilience

In the Gulf South, precast concrete is a crucial component of infrastructure development and disaster recovery strategies. It is a favored option due to its quick construction, resilience to inclement weather, affordability, and environmental sustainability. The Gulf South can improve the resilience of its infrastructure, reduce the amount of time needed to recover from disasters, and clear the path for long-term sustainable development and expansion by utilizing the advantages of precast concrete.

Educational Facilities of Tomorrow: Enhancing Learning Spaces with Architectural Precast Concrete

Imagine a busy school campus that is ablaze with student laughter, the sound of learning, and the promise of a day when innovation meets education. One material stands out for its adaptability, durability, and visual appeal as architects and educators work together to design the schools of the future: precast concrete.

Imagine a busy school campus that is ablaze with student laughter, the sound of learning, and the promise of a day when innovation meets education. One material stands out for its adaptability, durability, and visual appeal as architects and educators work together to design the schools of the future: precast concrete.

10 Ways Architectural Precast Concrete Can Help Shape Modern Educational Facilities

Facade Cladding: Schools can have a long-lasting, low-maintenance external finish with precast concrete panels. These panels can have their texture, color, and pattern changed to fit the architectural design and branding of the school. Precast panels also offer thermal insulation, which boosts energy efficiency and produces a comfortable interior atmosphere.

Architectural Features: Decorative arches, graceful columns, and elaborate facades are just a few of the eye-catching architectural characteristics that schools can design with precast concrete. Precast's adaptability makes it possible to incorporate elaborate patterns and creative elements, which improve the school buildings' aesthetic appeal and individuality.

Entrance Canopies: A warm and practical touch can be added to school entrances with precast concrete entry canopies. They create a focal point that embodies the school's identity and design ethos while providing weather protection for both students and visitors.

Interior Walls: The structural stability and acoustic insulation offered by precast concrete interior walls promote a positive learning atmosphere. To create visually appealing interiors, schools can select from a variety of finishes, including exposed aggregate, textured patterns, and smooth surfaces.

Staircases: Stairs made of precast concrete give versatility in design in addition to being strong and long-lasting. They can be shaped into a variety of forms and designs, adding creative features like integrated lighting or ornate railings, to create useful and eye-catching focal pieces for school buildings.

Outdoor Amphitheaters: Precast concrete guarantees weather resistance and longevity, making it perfect for concerts and activities held at schools. The tiered seating can include built-in features like lighting and sound systems and can be adjusted for the best viewing angles.

Sculptural Installations: Using precast concrete to create sculptures brings a touch of art into educational settings. These installations can be anything from abstract paintings to sculptures with themes that correspond with the school's instructional objectives or core values.

Window Surrounds: Precast concrete window sills and surrounds add a decorative element to educational buildings while serving practical purposes like thermal performance and moisture prevention. They can be altered to improve curb appeal and blend in with the architectural design.

Landscaping Elements: Precast concrete features that improve outdoor areas on school property include planters, benches, and retaining walls. These components can be made to mix in perfectly with the overall landscape design, and they are weather-resistant, long-lasting, and practical.

Custom Design Elements: There are countless options for unique design features in schools, such as artwork, signs, and ornamental panels, thanks to precast concrete. These components provide schools a more distinctive and personalized look while also improving their visual attractiveness from the inside and outside. Schools can create visually attractive places that reflect their identity and values by using instructional themes, inspirational phrases, logos, and themed designs.

Future Architectural Trends for Schools

It is well known that architects will witness a growing emphasis on sustainability, resilience, and adaptability in school architecture in the coming decades. Green areas, renewable energy sources, and energy-efficient building materials will all become increasingly commonplace. Schools will also look for architectural features like flexible learning spaces and technology integration that can be adjusted to changing educational demands and are resistant to natural disasters.

Precast concrete can be quite helpful in matching these trends. This is because it provides sustainable solutions such as recycled materials, resilience to adverse weather, and adaptability in the creation of all types of school structures. Because it is prefabricated, construction can be completed more quickly, with less waste, and with the seamless integration of cutting-edge design components. Precast concrete gives architects the adaptability and functionality they need to create durable, sustainable, and modern learning environments as schools continue to change.

Unleashing Creativity: The Impact of Precast Concrete on School Architecture

In terms of originality, precast concrete is a shining example of modern school architecture. Architects and educators alike favor it for its adaptability, robustness, and visual appeal. Precast concrete's capacity to blend practicality and aesthetic expression promises to continue influencing school architecture as we look to the future of education. Precast in schools is just getting started, but it has great promise for creating engaging learning environments in the future.

Accelerated Construction: Advantages of Using Precast Concrete in School Building Projects

Efficiency is critical in the fast-paced field of school construction. With its unmatched durability, cost-effectiveness, and expedited timescales, precast concrete has become a game-changer. This blog examines how precast concrete technologies, which shorten construction times and improve sustainability, are transforming school building projects. Learn about the numerous advantages of using precast concrete in school infrastructure for a future that is more durable and efficient.

Efficiency is critical in the fast-paced field of school construction. With its unmatched durability, cost-effectiveness, and expedited timescales, precast concrete has become a game-changer. This blog examines how precast concrete technologies, which shorten construction times and improve sustainability, are transforming school building projects. Learn about the numerous advantages of using precast concrete in school infrastructure for a future that is more durable and efficient.

What is Precast Concrete and Accelerated Construction?

Precast concrete is produced under controlled conditions off-site, involving the fabrication of structural components like walls, columns, and beams. This technique expedites the building process by enabling concurrent on-site preparation while parts are manufactured off-site. When compared to traditional methods, the ease of assembly required to assemble these precast pieces after delivery greatly minimizes construction time.

Precast concrete construction expedites project timetables, reduces costs, and enhances quality control. This method has significant benefits for schools since it reduces disturbances, allows for design flexibility, and guarantees that buildings are ready for occupancy more quickly, all of which help to effectively satisfy educational expectations.

Advantages of Precast Concrete in School Building Projects

Precast concrete construction has several benefits for schools, especially when it comes to accelerated construction. Precast components transform the way schools are designed and constructed, offering benefits including increased safety and cost-effectiveness.

Cost Efficiency and Time Savings

Construction of schools is streamlined by precast concrete, which lowers labor costs and accelerates project completion times. Quicker occupancy, lower costs for temporary facilities, and faster delivery of educational services are all benefits of precast.

Durability and Longevity

Precast materials are durable and able to withstand frequent use in educational settings. Accelerated construction ensures long-term durability, lowers maintenance costs and extends the life of buildings without sacrificing quality.

Flexibility in Design and Customization

For schools, precast concrete offers a wide range of design possibilities in terms of finishes, shapes, and colors. Accelerated construction paired with precast addresses a variety of practical and aesthetic needs while quickly accommodating changes.

Sustainability and Environmental Benefits

The eco-friendly qualities of precast concrete complement current trends in school architecture. Being able to build faster with precast reduces waste, energy use, and environmental effects on the job site.

Enhanced Safety and Security

Because their sturdy construction makes them impervious to vandalism and natural disasters, precast components enhance school safety. In addition to reducing safety hazards during the building phase and ensuring timely completion, precast with accelerated construction creates secure learning environments.

There are many advantages to use precast concrete in school construction projects. Because of its affordability, resilience, adaptability, sustainability, and safety features, it's the best option for modern educational buildings looking to build faster without sacrificing quality.

Summit Country Day School Addition: Accelerated Construction with Precast Concrete in Historic School Renovation

This project involved a renovation and new construction at a historic school building, where safety considerations and time constraints required innovative solutions for construction during the summer months only. With a strict deadline of 13 weeks and a budget of $10M, the project faced significant challenges in completing the work efficiently and safely.

The project faced several challenges, including a tight schedule of 13 weeks for new construction and renovation, limited lay down space, and the critical need to match the existing 1888 architecture of the school.

Precast concrete emerged as the ideal solution for the new construction, utilizing an Integrated Project Delivery (IPD) approach with hand-selected consulting and construction resources. This involved leveraging design assistance and building information modeling (BIM) technologies, as well as choreographing the work for completion within the 13-week timeframe.

Benefits of Precast Concrete:

Accelerated Construction: The use of precast components facilitated a rapid construction schedule, including the erection of a five-story structure and envelope in just 21 days.

Space Efficiency: Precast panels were delivered and erected in a carefully sequenced manner, overcoming the challenge of limited lay-down space and ensuring efficient construction.

Historical Matching: Precast panels were customized to match the classic Georgian architecture of the existing 1888 school building, seamlessly blending the new construction with the historic structure.

Innovative Formwork: Complex geometry and architectural details, such as the mansard roof, were achieved through innovative formwork techniques, showcasing the versatility of precast concrete in replicating intricate designs.

The successful completion of this historic school renovation highlights the advantages of using precast concrete in accelerated construction projects with strict time constraints and architectural requirements.

Building Tomorrow's Schools Today: Precast Concrete's Role in Accelerated Construction

There are many benefits to using precast concrete in school building projects, one of which is faster construction. Modern school constructions choose precast because of its capacity to improve structural integrity, lower interruptions to the construction site, expedite timetables and offer cost-effective alternatives. By utilizing precast technology, educational institutions can provide high-quality, long-lasting, and visually beautiful buildings for both professors and students, all while efficiently achieving their construction goals.

Design Trends with Precast Concrete in Educational Facilities

Picture this: a classroom buzzing with energy, where walls don't just hold up the roof but inspire minds, and floors aren't just surfaces but pathways to discovery. Prepare to be transported into a world where imagination meets innovation, where precast concrete isn't just a material but a storyteller in the narrative of education.

Picture this: a classroom buzzing with energy, where walls don't just hold up the roof but inspire minds, and floors aren't just surfaces but pathways to discovery. Prepare to be transported into a world where imagination meets innovation, where precast concrete isn't just a material but a storyteller in the narrative of education.

Benefits of Using Precast Concrete in Educational Facilities

When used in educational institutions, precast concrete has several advantages.

Because of its natural resilience, it lasts longer in high-traffic areas and gradually requires less maintenance.

Design flexibility makes customized learning environments possible, which boosts student creativity and engagement.

The sustainability qualities of precast concrete provide environmentally friendly construction methods that complement the environmental objectives of educational institutions.

Precast concrete is a recommended material for contemporary educational facility design because of these advantages. When combined, they provide engaging and practical learning environments that prioritize students' health, safety, and academic performance.

Design Trends with Precast Concrete

Innovative design concepts have revolutionized educational facilities by transforming conventional classrooms into dynamic learning spaces. Modern design techniques paired with precast concrete transform learning environments to improve student participation, health, and academic performance.

Natural Light and Open Spaces

Designing educational spaces with lots of natural light and open floor plans promotes a good learning environment. Students benefit from natural light as it increases their alertness and focus, and they may collaborate, be creative, and feel free in open areas. Precast can support longer spans, which means fewer columns and walls to break up open spaces.

Technology-Friendly Features

Modern classroom technology, such as interactive whiteboards, smart boards, and digital resources, improves student involvement and the efficacy of instruction. These characteristics support the development of digital literacy and interactive learning experiences. Precast can be integrated with all types of systems, from plumbing to electrical, to provide the best of both worlds in terms of construction and technology.

Biophilic Design Elements

Using biophilic design elements, such as indoor plants, green walls, and natural materials, fosters wellbeing and a connection between students and the natural world. Improved air quality, less stress, and a peaceful, motivating environment for learning are all benefits of biophilic design. Precast is mold-resistant and is a perfect home for plants and other natural materials.

Modular and Flexible Furniture Arrangements

Flexible seating arrangements and modular furniture enable classrooms to change to accommodate various teaching philosophies and student preferences. This adaptability promotes teamwork, active learning, and the personalization of learning environments to suit various educational requirements. Precast can be used to create spaces that allow for the free movement of desks and other school furniture, supporting this adaptability.

Sustainable Design Practices

Incorporating eco-friendly elements like green roofs, energy-efficient lighting, and rainwater harvesting systems increases environmental consciousness and lessens the ecological impact of educational structures. Sustainable design principles encourage students to adopt sustainable behaviors and are consistent with educational institutions' environmental stewardship values. Precast not only reduces future maintenance for schools but also provides resistance to storms, increasing structures' lifespans.

Best Practices for Implementing Precast Concrete in Educational Buildings

Adherence to best practices and cooperative efforts are necessary to successfully use precast concrete in educational facilities. To ensure that design purpose matches educational objectives, key issues include efficient communication and collaboration among architects, designers, educators, and construction teams. Maintaining long-term functionality and beauty requires careful consideration of accessibility, safety regulations, acoustic performance, and routine maintenance and upkeep techniques. Educational buildings can use the advantages of precast concrete and create inspirational and useful environments that promote student learning, creativity, and wellbeing by prioritizing these best practices.

Future Directions and Innovations

Exciting developments and inventions in precast concrete for educational buildings are anticipated in the future. Some of the developments that are anticipated include more integration of smart technologies to improve learning, the creation of environmentally friendly building materials and techniques, and the use of flexible and adaptive designs to meet changing needs in education. These developments align with the continuous development of learning environments, guaranteeing that precast concrete will be essential to constructing dynamic, motivating, and long-lasting learning spaces for future generations.

Final Thoughts

The design trends, best practices, and future innovations discussed showcase the transformative potential of precast concrete in creating inspiring and functional educational buildings. To delve deeper into how precast concrete is the right choice for schools, we invite you to view our school-focused resources. Explore the benefits, success stories, and expert insights demonstrating why precast concrete is the ideal solution for modern educational environments!

Cost-Efficiency and Longevity: Evaluating the Life Cycle of Precast Concrete

Precast concrete is unique among building materials because of its affordability, toughness, and adaptability. By analyzing its extensive life cycle assessment, affordability, resilience, and environmental sustainability, we reveal its significant influence on contemporary building methods and infrastructure advancement.

Precast concrete is unique among building materials because of its affordability, toughness, and adaptability. By analyzing its extensive life cycle assessment, affordability, resilience, and environmental sustainability, we reveal its significant influence on contemporary building methods and infrastructure advancement.

Understanding Precast Concrete

Precast concrete is a versatile and durable construction material that is made off-site in controlled environments and then delivered to construction sites. It includes a wide variety of structural components made with molds and curing procedures, such as walls, columns, beams, slabs, and panels.

Precast concrete has several benefits, such as quick installation that minimizes labor on-site, high-quality manufacture under strict quality control procedures, and the capacity to modify designs to meet project-specific specifications. Its applications cover infrastructure, commercial, industrial, and residential buildings, making it a top pick for long-lasting and reasonably priced building solutions.

Precast’s Life Cycle Assessment (LCA)

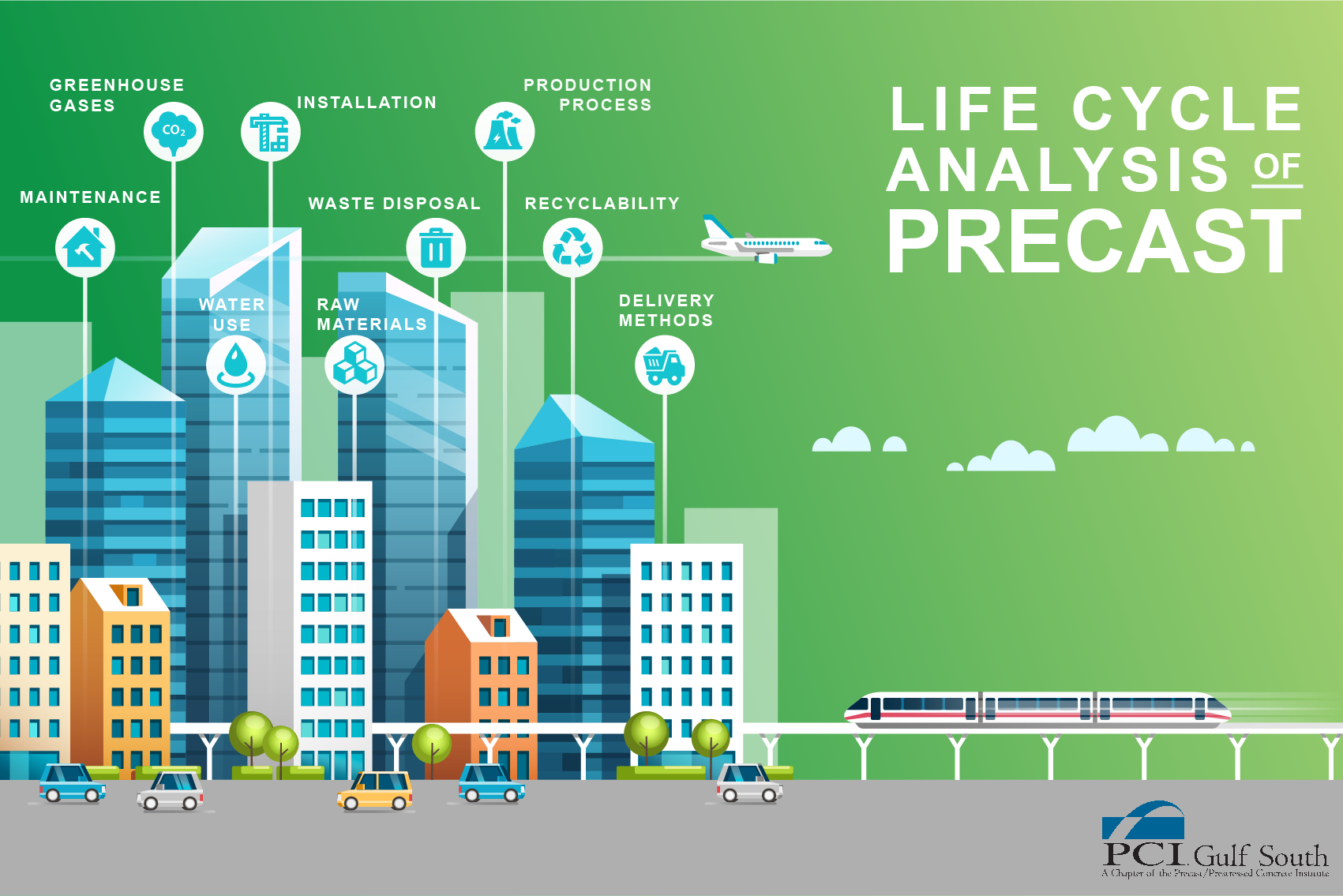

A systematic analysis technique called life cycle assessment (LCA) is used to assess how a product or process will affect the environment at each stage of its life cycle, from the extraction of raw materials to disposal. LCA is essential for evaluating sustainability indicators in the context of precast concrete, including:

greenhouse gas emissions

water use

environmental impact of extracting raw materials

energy-intensive production processes

transporting completed goods

installation techniques

maintenance needs

end-of-life issues like disposal or recyclability

By conducting a thorough life cycle assessment (LCA), stakeholders can maximize precast concrete's environmental performance, pinpoint opportunities for development, and advance sustainable practices in the building sector.

Cost-Efficiency of Precast Concrete

Precast concrete is becoming widely used in construction projects due in large part to its cost-effectiveness. Precast concrete offers considerable labor, time, and cost reductions over typical cast-in-place concrete processes. Construction schedules are shortened, and the amount of manpower needed on site is reduced because of the off-site manufacturing method, which enables simultaneous production and on-site preparation.

Precast concrete is more affordable when production conditions are regulated, manufacturing procedures are standardized, material waste is decreased, and quality control is enhanced. Additionally, because precast concrete is naturally durable and resistant to environmental deterioration, using it can result in lower maintenance expenditures over the course of a structure's lifetime.

Project stakeholders can attain expedited construction timelines, decreased project costs, and improved long-term value through the reduction of maintenance and operations expenses by utilizing the cost-effectiveness of precast concrete. Because of this, precast concrete is an excellent option for building projects in a variety of industries that are driven by efficiency and cost concerns.

Longevity and Durability

Precast concrete's lifespan and durability are important factors to consider when evaluating its life cycle. Precast concrete buildings are famous for their extraordinary strength, resistance to weathering, and long-term durability in a variety of environmental circumstances. For infrastructure development, precast concrete is an affordable and environmentally friendly option because it requires less future maintenance and has a longer lifespan than traditional construction techniques.

Precast concrete's durability is further increased by its resistance to fire, corrosion, and seismic stresses, which guarantees structural integrity and safety throughout time. These characteristics make precast concrete the perfect choice for important infrastructure projects, including roads, bridges, buildings, and other structures that need to last a long time.

Environmental Sustainability

Precast concrete is acknowledged for making major contributions through its life cycle to environmentally sustainable building practices. Compared to conventional concrete processes, its production process minimizes waste formation, consumes less energy, and efficiently uses the ingredients. Precast concrete buildings also have a smaller carbon footprint and, because of their improved thermal qualities, improve building energy efficiency.

Precast concrete's capacity to be recycled helps to further advance sustainability by lowering trash sent to landfills and preserving natural resources. Precast concrete is the material of choice for environmentally aware construction projects that aim to reduce their negative effects on the environment and encourage sustainable growth because of these advantages over other materials that are in line with green building standards and certifications.

Future Trends and Innovations

Precast is expected to continue to progress and innovate in order to improve performance, efficiency, and sustainability. The development of sustainable materials and practices to lessen environmental impact, automation of production processes for increased efficiency and quality control, and the integration of digital software like BIM for precise modeling and coordination are some of the key trends.

Precast components that are both lightweight and highly durable are examples of structural design innovations that are expected to open up new avenues for creative architecture and robust construction. These patterns point to a bright future for precast concrete in satisfying the changing needs of contemporary buildings.

Building Tomorrow Today: The Sustainable Life Cycle of Precast Concrete

The life cycle analysis of precast concrete demonstrates its many benefits regarding longevity, affordability, and environmental sustainability. Precast concrete technology is positioned to play a larger part in the construction of sustainable and resilient infrastructure as long as innovation propels further advancements in the field, thereby influencing global construction trends.

Integrating Precast Concrete for Visual Appeal in School Structures

In the realm of educational architecture, aesthetics play a vital role in creating inspiring learning environments. Among the myriad of construction materials available, precast concrete stands out for its versatility and potential to enhance visual appeal.

In the realm of educational architecture, aesthetics play a vital role in creating inspiring learning environments. Among the myriad of construction materials available, precast concrete stands out for its versatility and potential to enhance visual appeal. In this blog, we delve into the integration of precast concrete in school structures, exploring its customization options, benefits, and successful applications. Join us as we unravel the art of blending functionality with aesthetics in educational design.

Precast can be used on everything from wall panels to concrete stairs to help match a school’s architectural and aesthetic needs

Understanding Precast Concrete

Precast concrete refers to concrete elements that are manufactured off-site in controlled environments before being transported to the construction site for installation. This construction method involves casting concrete in a reusable mold or form, allowing for precise control over the quality and finish of the final product. Precast concrete components are commonly used in various construction projects, including schools, due to their versatility, durability, and cost-effectiveness. Unlike traditional cast-in-place concrete, precast concrete elements can be produced in a factory setting, where environmental conditions can be carefully monitored, resulting in consistent quality and uniformity. Additionally, precast concrete offers design flexibility, enabling architects and engineers to create intricate shapes, textures, and patterns. With its ability to withstand harsh weather conditions, fire, and impacts, precast concrete is an ideal choice for constructing resilient and long-lasting school structures that prioritize both aesthetics and functionality.

Importance of Visual Appeal in School Structures

The visual appeal of school structures plays a crucial role in creating an environment conducive to learning and development. Aesthetically pleasing architecture can positively impact students' attitudes, behavior, and overall academic performance. Bright, well-designed spaces can foster a sense of pride and ownership among students and staff, promoting a welcoming and inspiring atmosphere. Research has shown that visually stimulating environments can enhance creativity, concentration, and motivation, leading to improved educational outcomes. Additionally, aesthetically pleasing school buildings can contribute to the community's perception of the institution and its values. By investing in attractive and well-maintained facilities, schools demonstrate their commitment to providing a high-quality learning environment for students and staff alike. Therefore, prioritizing visual appeal in school architecture is essential for creating engaging and supportive educational spaces that promote student success and well-being.

Advantages of Integration of Precast Concrete in School Structures

Integrating precast concrete into school structures offers numerous benefits that contribute to the overall quality and longevity of the buildings. One of the primary advantages is the durability and resilience of precast concrete materials, which can withstand harsh weather conditions, impacts, and wear and tear over time. This durability translates to reduced maintenance costs and prolonged lifespan, making it a cost-effective choice for school construction projects. Additionally, precast concrete is highly versatile and can be customized to meet specific design requirements, allowing architects to create visually appealing and functional spaces that enhance the learning environment. The use of precast concrete can expedite construction timelines by minimizing on-site labor and reducing construction waste. With its combination of strength, versatility, and efficiency, integrating precast concrete in school structures ensures that educational facilities are built to last and provide optimal performance for generations to come.

Customization Options for Schools with Precast Concrete

The versatility of precast concrete offers an array of customization options for school structures, allowing architects to bring their design visions to life while meeting the specific needs of educational environments. With precast concrete, schools can achieve a variety of architectural styles, from traditional to contemporary, with ease. Precast panels can be molded into various shapes, textures, and finishes, providing endless possibilities for creating unique facades and interior elements. Additionally, precast concrete allows for the integration of decorative elements, such as patterns, logos, and signage, further enhancing the aesthetic appeal of school buildings. Whether it's creating a striking entranceway, incorporating artistic features, or adapting to site-specific conditions, precast concrete offers the flexibility to tailor school designs to the preferences and requirements of students, staff, and the surrounding community, ultimately contributing to a more engaging and inspiring learning environment.

Precast Is the Right Choice For Schools

Integrating precast concrete in school structures offers a multitude of benefits, from enhanced durability and cost-effectiveness to design flexibility and customization options. By prioritizing visual appeal and functionality, educational institutions can create inspiring learning environments that promote student success and well-being. As schools continue to evolve to meet the needs of future generations, precast concrete stands as a reliable and versatile building material for constructing resilient and aesthetically pleasing educational facilities.

Soundproofing Solutions using Precast Concrete

In the world of construction, one advantage oftentimes put towards the bottom of the list of benefits of using precast is soundproofing. Whether its a commercial structure or a residential building, precast can provide soundproofing so all occupants feel comfortable in their individual spaces.

In the world of construction, one advantage oftentimes put towards the bottom of the list of benefits of using precast is soundproofing. Whether its a commercial structure or a residential building, precast can provide soundproofing so all occupants feel comfortable in their individual spaces. Keep reading to learn how precast is one of the best materials for soundproofing structures of all sizes and types!

Understanding Acoustic Challenges

It's important to understand the acoustic issues that precast concrete can solve. There is a pressing demand for creative acoustic solutions due to common noise-related problems in both residential and business settings. Unwanted noise has been found to have a substantial negative influence on productivity and well-being in addition to upsetting peace of mind for occupants.

The sanctity of dwellings in residential settings can be compromised by noise from neighboring rooms, which lowers quality of life. Loud noises in business settings can impair focus and efficiency of employees, raising stress levels. The precast sector uses innovative solutions that go beyond traditional materials to solve these acoustic problems.

The Science Behind Soundproofing

Precast’s distinct structure and composition function as strong barriers to sound, reducing undesired noise and obstructing the transmission of sound. The industry has developed novel applications by comprehending sound's subtleties and demonstrating precast concrete's effectiveness in producing acoustically superior rooms. These methods make soundproofing more feasible and establishes precast concrete as a fundamental component of building and architectural solutions that aim for superior acoustics.

Benefits of Precast Concrete for Soundproofing

Unmatched in its benefits for soundproofing applications, precast concrete opens up a world of acoustic design. Precast concrete's natural ability to reduce noise fosters peaceful surroundings by separating occupants from outside distractions.

Noise Reduction: Unwanted noise is efficiently reduced and mitigated by precast concrete, making interiors cozier and quieter.

Thermal Insulation: Precast's ability to regulate temperature and provide excellent acoustics also improves overall comfort.

Versatility: Precast concrete can be used for a wide range of purposes, such as wall panels and flooring systems, which allows it to be tailored to meet different soundproofing requirements.

Durability: Precast concrete's natural strength guarantees long-lasting soundproofing solutions that continue to work over time.

Cost-Effectiveness: Precast concrete frequently proves to be a cost-effective option when compared to conventional soundproofing techniques, offering exceptional acoustic performance at an affordable price.

PCI’s Designer Notebook on Acoustics explains architectural acoustics and its use within the industry. It contains information on sound levels, transmission loss, and absorption, as well as acceptable noise criteria and composite walls considerations.

Applications in Residential Spaces

Precast concrete is a game-changer in residential structures, providing unmatched soundproofing options for homes and apartments. Precast concrete finds creative uses in residential soundproofing, redefining comfort and tranquility with wall panels and flooring systems. This focus on residential applications serves to highlight precast concrete's important role in improving the acoustic landscape of residences, offering residents who want silence in their personal havens a comfortable living environment.

Commercial and Industrial Applications

Precast concrete provides a strategic solution in the field of commercial and industrial acoustics, specifically designed to meet the unique soundproofing requirements of these settings. Precast has had its effectiveness proven in industrial environments by demonstrating how soundproofing techniques made of precast concrete lead to increased productivity and better working conditions for employees.

Precast and Soundproofing Go Hand in Hand

It can be easily seen why precast concrete excels as a soundproofing material in modern-day construction. With its inherent ability to dampen sounds, precast is perfect for structures where individual spaces need acoustic separation.

Contact us or one of our producers today to learn how precast can be used on your next project!

Concrete Revolution: Crafting Sustainable Futures with Precast Infrastructure

Among the many building materials that are accessible, precast concrete is a reliable option for creating the framework of sturdy infrastructure. Precast concrete has several uses, from unmatched durability and quick construction to strict quality control and environmentally friendly methods.

Among the many building materials that are accessible, precast concrete is a reliable option for creating the framework of sturdy infrastructure. Precast concrete has several uses, from unmatched durability and quick construction to strict quality control and environmentally friendly methods. This article highlights the inherent advantages, practicality, and affordability of using precast concrete in infrastructure projects by examining its use in railroads, bridges, water management, and utility structures.

Advantages of Precast Concrete in Infrastructure Development

Examining the intrinsic benefits of precast concrete in creating infrastructure demonstrates how it has a revolutionary effect on construction techniques. Precast concrete is a strong option with qualities like sustainability, efficiency, and durability transforming modern infrastructure building.

Durability and Strength

Precast concrete offers unmatched resistance to wear, corrosion, and severe weather compared to traditional building materials. Because of its innate strength, which guarantees structural integrity throughout time, it is the best material for infrastructure where durability and resilience are critical.

Efficiency and Speed

Building projects are completed much faster when precast concrete is used. When parts are produced in quality controlled environments off-site, less work needs to be done on-site, which speeds up project completion and lowers labor expenses.

Quality Control

Precast concrete is produced in a controlled atmosphere that ensures consistently high quality, even better than on-site casting. Strict quality controls are implemented during production to guarantee accuracy and compliance with industry norms.

Sustainability

The low waste generated during manufacturing and the possibilities for recycling make precast concrete an environmentally beneficial material. Its extended lifespan, robustness, and energy efficiency support environmentally friendly methods of building infrastructure.

Applications of Precast Concrete in Infrastructure

Bridges and Highways

Precast concrete is widely used in bridge construction because it provides flexible deck, girder, and abutment components. Its exceptional strength and resilience make it a dependable option that guarantees resilience and longevity across various bridge types.

Railways and Mass Transit Systems

Precast concrete is used in railways and mass transportation systems for stations, track systems, tunnels, and viaducts. In transportation situations with heavy traffic, its robustness guarantees longevity and safety.

Water and Wastewater Management

Precast concrete water management structures include sewage systems, treatment plants, and reservoirs. Being able to resist corrosion and keep their structural integrity, these structures offer long-lasting solutions for water distribution, storage, and treatment.

Utility Structures

Precast concrete provides stability, protection, and resilience against environmental variables, essential for utility structures such as communication towers and electrical substations.

Cost-Effectiveness and Long-Term Benefits

Gaining insight into the financial elements of precast concrete in infrastructure construction allows for a more nuanced understanding of its long-term benefits and cost-effectiveness. The comprehensive analysis of lifespan costs and long-term benefits highlights the sustainability and economic feasibility of using precast concrete in infrastructure projects, even though upfront costs may differ.

Initial Costs vs. Life Cycle Costs

Precast concrete in infrastructure is cost-effective when long-term expenditures are compared to upfront costs. Precast concrete may seem like a slightly more expensive initial investment than standard materials, but there are significant long-term benefits. Because precast concrete is resilient and long-lasting, it requires less maintenance, repair, and replacement, which lowers life cycle costs for infrastructure projects. Additionally, the shorter project durations produced by the expedited building timeframes made possible by precast concrete components mean lower labor costs and less disturbance to the surrounding region. Precast components can be quickly assembled, which reduces downtime and speeds up infrastructure projects, lowering costs in the long run.

Minimized Downtime

Additionally, precast concrete's inherent strength and durability result in a longer service life, which reduces the need for frequent repairs or replacements. This endurance improves cost-effectiveness since precast concrete infrastructure is more resilient to weather, wear, and structural deterioration. Precast concrete is a financially sensible option for infrastructure projects looking for long-term sustainability and economical resource utilization due to its minimal lifecycle costs and decreased requirement for continuing maintenance.

Investing in Tomorrow: The Smart Choice of Precast Concrete for Lasting Infrastructure

Precast concrete's incorporation into infrastructure development is a shining example of efficiency and creativity. Its many benefits—from unmatched durability and construction efficiency to strict quality control and cost-effectiveness—highlight its crucial role in modern building techniques. Precast concrete exhibits versatility and dependability in various applications, including water management, railroads, bridges, and utility structures. The benefits of precast concrete are undeniable as we embrace the future of infrastructure development; it provides an environmentally friendly, long-lasting, and financially sensible way to construct the framework for our changing society.

Precast Concrete vs Tilt Up Concrete Wall Panels

Construction teams use prefabricated components more often to expedite the building process and provide the project owner with the desired functionality. Two popular types of prefabricated commercial building materials are tilt-up and precast construction. Is one better than the other, and where should each be used? As experts in the precast/prestressed concrete industry, this is how we see it.

Using appropriate equipment and technology with expert craftsmanship is essential in modern commercial buildings. Construction teams use prefabricated components more often to expedite the building process and provide the project owner with the desired functionality.

Two popular types of prefabricated commercial building materials are tilt-up and precast construction. Is one better than the other, and where should each be used? As experts in the precast/prestressed concrete industry, this is how we see it.

The Difference Between Precast vs. Tilt-up Construction

Concrete wall panels include tilt-up and precast varieties. They both function as supports for numerous stories, offering strong outside and internal walls. The locations and methods used to generate each vary:

Precast walls are manufactured, constructed, and cured at a factory before being delivered to a building site and put up.

Tilt-up panels are created with forms constructed on the building site, filled with concrete, allowed to cure, and then lifted into position using a crane.

What is precast concrete construction?

Precast concrete construction entails constructing buildings and/or concrete elements offsite and moving the finished structures or parts to their intended locations. Individual walls, beams, columns, and other structural components can be made with precast concrete. Alternatively, it may be used to create monolithic building modules ready to use after being transported and assembled at a job site.

The manufacture of precast concrete has several significant benefits. Because each precast component is cured in a controlled environment without needing to take into consideration inclement weather, precast concrete components or entire structures may be made for a larger range of worksites. Steel reinforcements and other materials can also strengthen precast concrete constructions.

What is tilt-up concrete construction?

At the installation site of a structure, tilt-up concrete construction entails pouring concrete into predetermined forms and letting it cure. After the concrete has cured, cranes and other equipment are used to raise the panels to their permanent locations.

In certain circumstances, this kind of concrete building may be beneficial. For example, it does away with the requirement of transporting full-size concrete pieces.

Factors To Consider When Deciding on Precast or Tilt-Up

Selecting between tilt wall and structural precast concrete building techniques for your project means you need first to assess your project's demands.

Location

When choosing between tilt wall and precast construction, the location of your project is a crucial consideration. Usual weather patterns won't impact the capacity to cast tilt wall panels on-site with a little preparation. On the other hand, severe weather can make casting at the project site impossible. All precast components are made offsite in quality-controlled manufacturing facilities and are unaffected by weather conditions. Additionally, many precast concrete suppliers are positioned strategically nationwide to offer affordable precast components.

Site Limitations

The ideal approach will partly depend on the site's limitations. Space for casting and curing is required to construct tilt walls on-site. Since precast is manufactured, cured, and cast in one location before being transported, it has few site restrictions.

Schedule

Precast concrete must be transported to the construction site from quality-controlled, roofed manufacturing plants with their own batch operations. Nonetheless, most precast manufacturers working in the construction industry nowadays can plan, cast, and deliver the precast promptly with ease. Tilt walls can provide shorter lead times since they may adapt to design modifications demands as the project progresses.

Structure

Tilt-up walls and precast concrete panels require more than just the concrete to finish a structure. Steel components are generally used alongside these construction materials to complete a building. Steel and precast concrete can be combined into one component, which means fewer trades on site. Precast can also be used to build all parts of a building, including the floor, roof, columns, and beams, making this option even more advantageous in terms of time and money savings.

Construction Sequencing

If the precast walls do not support any weight on the steel, steel can be installed ahead of the prefabricated walls. In this instance, the precast wall panels don't require bracing. They are immediately weldable to the steel frame. Typically, tilt walls are built first and require bracing to remain in place until the steel frame is constructed.

Budget

Each approach has financial advantages. Compared to other building processes, precast demands cheaper overall installation costs because of its short installation time and the requirement of less labor on site. Tilt walls can achieve strict deadlines while maintaining low prices but can add more time to the project schedule.

Building Size

Tilt wall panels can be broader than precast. Fewer panels to elevate means less manpower and equipment needed for the finishing trades, including caulking and repairing, though there will be a need for more labor to make the panels. Because precast needs to be transported, these components will have width limitations based on the jurisdictions they travel through. However, precast panels of up to 15 feet wide can be transported using tilt racks.

Tilt-Up Panels vs Precast Concrete Panels

Although tilt-up panels have become more capable, these structures will often be somewhat basic compared to the numerous applications for precast concrete panels. In other words, tilt walls generally are good for simple, box-like structures with minimal design elements. Precast, however, can be completely customized for any shape, size, or style a client may need for their structure. Because precast panels may be produced year-round, project designers can anticipate reduced prices and shorter lead times. Precast offers design freedom to project teams.

Precast concrete panels and tilt-up panels can bear weight, which allows them to efficiently move the weight from the walls, floor, and roof. Usually, load-bearing walls allow you to maximize the internal space in your building by removing the need for extra columns.

When you contrast precast with tilt-up construction, you'll find that the former is a more resilient building material. Tilt-up panels typically have psi values of about 4,000. In contrast, precast concrete panels have psi levels of at least 5,000 and occasionally more. As a result, you should anticipate that precast concrete panels will require less ongoing upkeep.

Thermal Efficiency & Insulation

Concrete has a relatively low R-value in the absence of insulation. So, it's important to ensure insulation is involved if the structure being built will be a workplace, school, or other building where people will be working regularly.

The insulation within the backup wall determines the thermal efficiency of tilt-up construction. This additional phase in the construction process will make walls heavier and thicker.

With precast construction, thermal efficiency is attained naturally. Wherever it is feasible, precasters can add insulation to wall panels.

Effective thermal efficiency offers long-term savings and a high return on investment. It enables owners to better regulate the temperature for particular items or keep their occupants comfortable. In the end, precast concrete panels have been proven to reduce heating and cooling expenses by up to 25%.

Misconceptions About Precast Construction

Some people worry that masons and other conventional building specialists may lose their employment to precast construction. The truth is that there is a labor shortage at the moment, which makes it challenging to locate enough qualified personnel to finish big projects on time. When precast building materials are used, a construction business can use fewer workers while adhering to budgets, schedules, and quality standards.

There is also a misperception that precast buildings are ugly and uninteresting. On the contrary, precast can have a variety of color treatments, including limestone, brick inlays, and other architectural design elements, making it appear like the "real thing." Precast can also contain long-lasting architectural elements like window frames and sills. Precast construction is sometimes seen as just a large gray box, but it can also be a creative method to create a beautiful facility while saving money and time. Below are just a few examples of the versatility of precast.

For some, flexibility is an issue as well. Precast construction might not seem to be ideal for future growth at first. This myth emphasizes how crucial it is to collaborate with a construction manager who can help with master plan development. Precast panel systems can be planned with knockout panels and well-placed doors to handle future building expansions.

Precast Concrete Has Many Benefits Over Tilt-Up Concrete

Site managers and other executives must understand the key distinctions between tilt-up and precast concrete building processes to select the best construction style for their requirements. The advantages of precast concrete buildings make it a better option for many worksites and has the added benefits of increased resilience, versatility, and sustainability compared to tilt-up concrete.

How to Make Your Company Attractive to Job Seekers

Any precast producer will find it challenging to find competent and motivated people in today's competitive labor environment. How can you differentiate your business from the competition and persuade potential hires that you are the right fit?

Any precast producer will find it challenging to find competent and motivated people in today's competitive labor environment. How can you differentiate your business from the competition and persuade potential hires that you are the right fit?

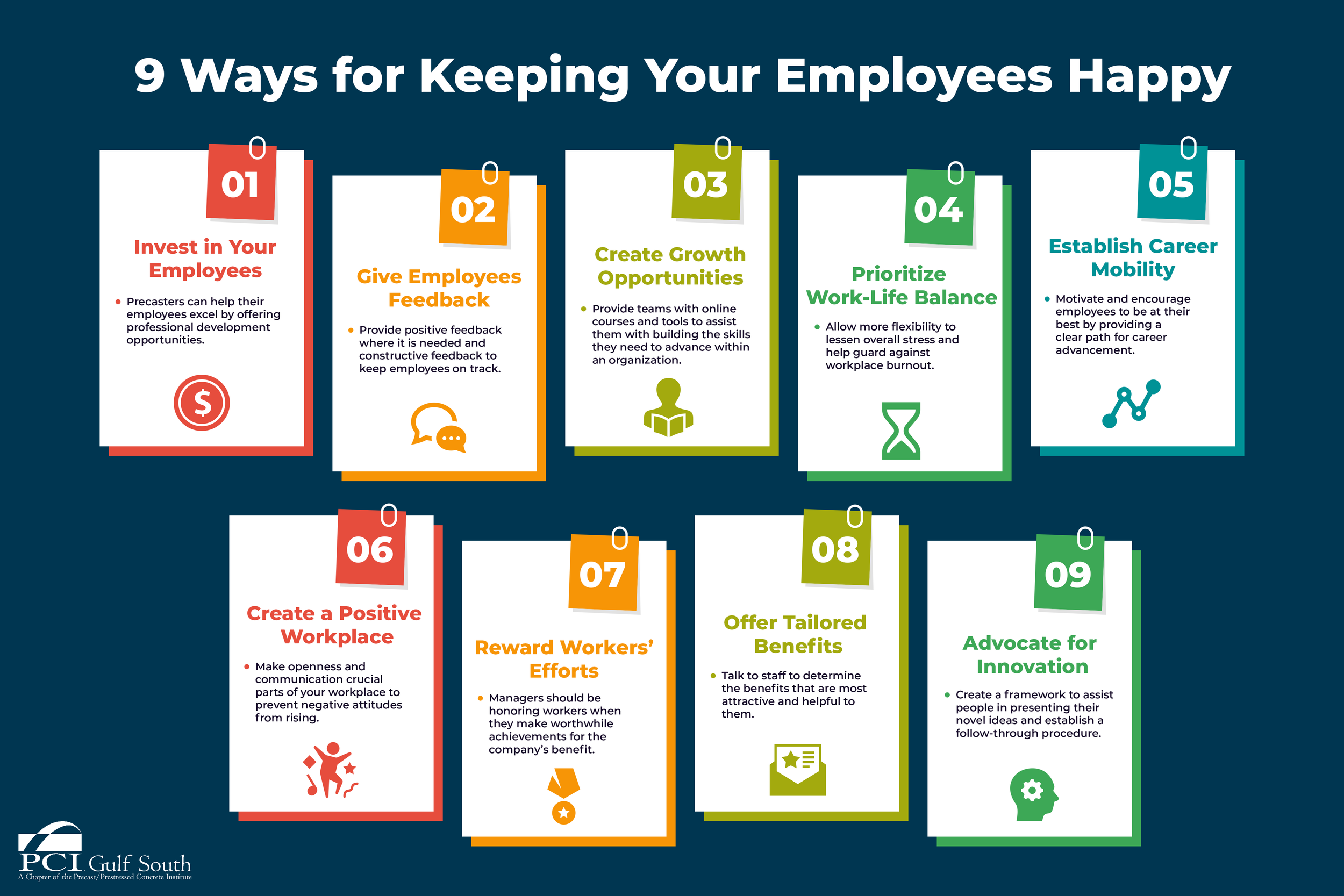

The following tips will help you build an attractive business to gain the attention of the applicants you are searching for.

Showcase Your Culture and Values

Offering top applicants a wonderful environment to work in is one of the finest methods to draw them in. A healthy firm culture, sometimes called organizational and corporate culture, engages employees, making them more productive and devoted.

Your company's culture and principles are among the first things job searchers check for when exploring your company's website, social media accounts, or job boards. They are interested in your work environment, team, and mission and how well those things mesh with their objectives and preferences.

Use genuine stories, testimonies, images, and films that illustrate your accomplishments, difficulties, diversity, and influence to communicate your culture and values effectively.

Focus on Having Great Benefits and Compensation

Your benefits and perk package is another aspect that affects job searchers' choices. What other benefits do you provide to entice and keep talent?

Most professionals desire more than just collecting a check as compensation for their efforts. Job seekers typically demand additional benefits like medical insurance, PTO, and retirement plans in addition to a competitive salary. They also want to work for organizations that provide benefits like remote or hybrid work options, flexible work schedules, reimbursement for education, and other benefits.

If you're having problems luring job seekers, evaluate your compensation package and see if there are any opportunities to make it better. In a competitive employment market, matching or exceeding today's top performers' high standards is a way to stand out.